With over 250 PEF systems installed worldwide, we are the world’s leading provider of Pulsed Electric Field (PEF) systems to the food, beverage and scientific industries. Our PEF experts, in collaboration with a global network of regional agents and technology partners, provide PEF technology tailored to the specific needs of our clients.

Elea PEF solutions help to foster sustainable practices and solutions for food production whilst providing greater returns and new opportunities for our clients. We will continue developing the science, systems and people behind this exciting technology and look forward to bringing the PEF Advantage to many new food products soon.

The Elea team

Prof. Dr. Stefan Toepfl

Jimmy Kinsella

Dr.-Ing. Claudia Siemer

Kevin Hill

Johannes Pfeiffer

William Cardwell

The Elea heads of departments

With more than 30 members of staff, the Elea team includes seasoned process, electrical and mechanical engineers, food technologists, biotechnologists, and a diverse array of other experts – all collaborating to drive new food innovations and deliver the best PEF solutions.

Six reasons why we are the world’s leading provider of PEF solutions to the food and beverage industry

Complete PEF solutions

We offer product testing, application support, system customisation, installation support and training, and post-sales care, all tailored specifically to your needs.

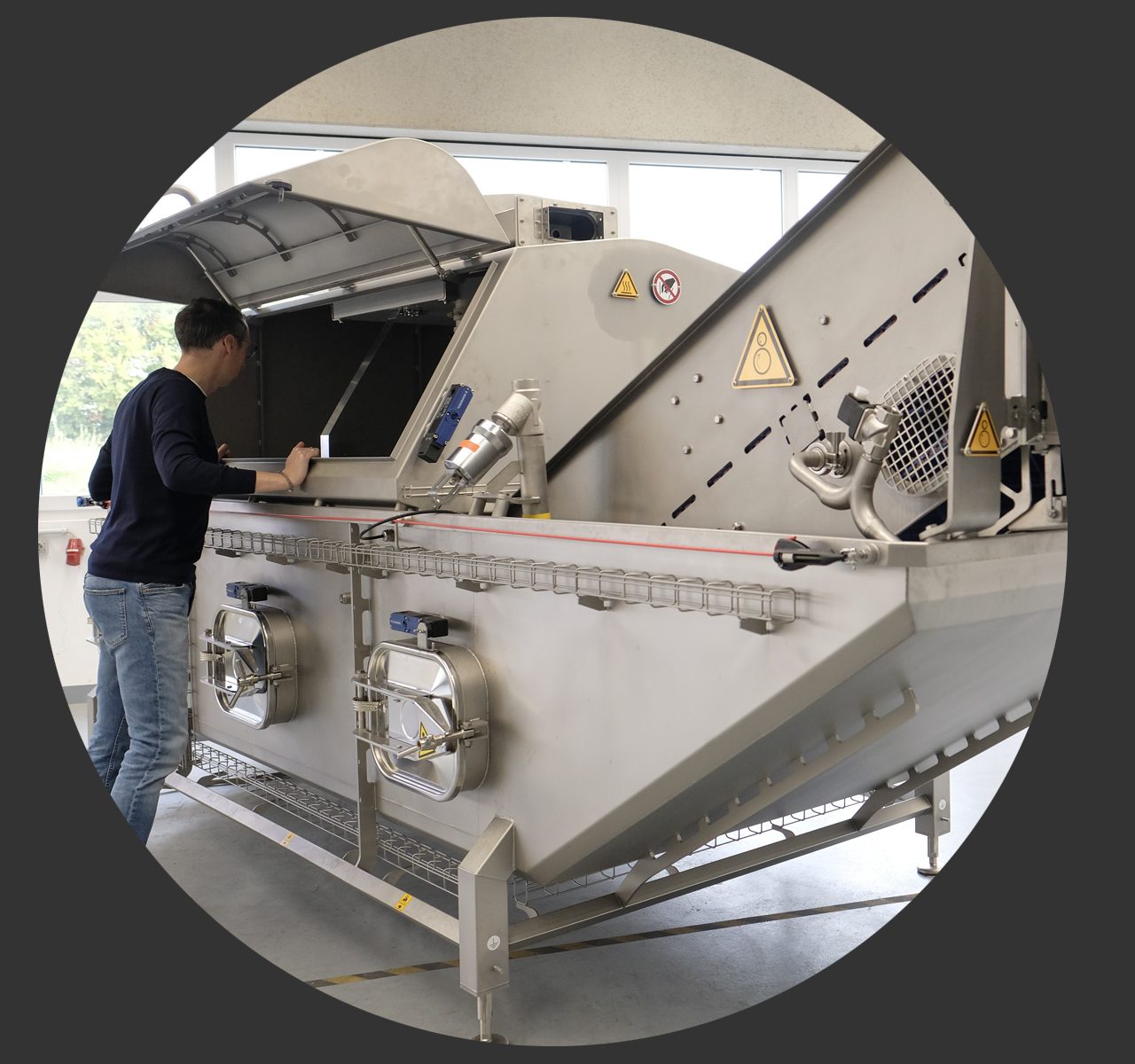

Designed and built by Elea

We offer the broadest range of customisable systems for liquid and solid foods, designed and built by us in Germany.

PEF expertise

Our team comprises – engineers, food technologists, bio-technologists and process engineers, all specialists in PEF and all focused on getting the best PEF solution for your products.

PEF innovation

We were the first company in the world to install industrial-scale systems for food and beverages and the first to provide pilot-scale systems for PEF R&D. We continue to innovate and refine our systems for current and future applications.

PEF Pioneering & R&D

The Elea R&D team, working from our custom-built pilot hall, continues to expand PEF’s potential and add to our portfolio of PEF applications. Currently, Elea owns more than 30 patents and patent applications.

System & application support

We offer 24-hour remote monitoring and on-site support options to ensure your continuous and efficient operation. In addition, we offer application support to ensure that you get the best result for your product from PEF.

Some of our clients and partners

Many of our clients require strict confidentiality about their PEF solution so special thanks to those who have let us use their logo.

“As PEF is applicable to all products where quality counts, it will become the preferred industry technology.”

Prof. Dr. Stefan Toepfl

Managing Director

The history of PEF and some Elea milestones

Early days

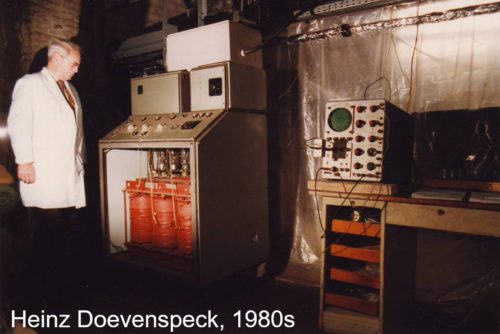

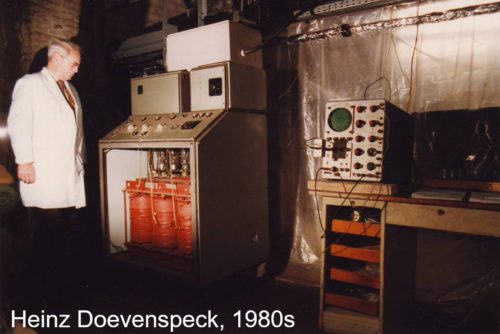

Heinz Doevenspeck published the first reports on Pulsed Electric Fields in the 1960s. He reported on the cell disruption effect and suggested its use to improve mass transfer processes, such as separation and drying, as well as the induction of microbial inactivation without a substantial amount of heating.

First system development

Thyssen Krupp followed up the work of Doevenspeck in the 1980s when a group including Heinz Doevenspeck and Werner Sitzmann installed the first industrial scale systems in the fish meal industry. Goals were set high, but unfortunately, the power-switching technology was not sufficiently developed enough.

Early stage research projects

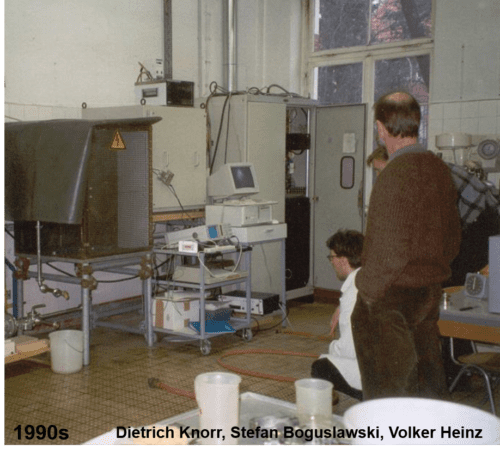

In the early 1990s, there were a number of PEF research projects in the EU and the US. At Berlin University of Technology (TUB) the possibility to induce plant cell permeabilization and to inactivate microorganisms was investigated by a group led by Dietrich Knorr.

In the US, researchers at the Ohio State University (workgroup around Howard Zhang) and Washington State University (Gustavo Barbosa´s work group) focused on microbial decontamination of liquid products. A number of lab and pilot scale systems for treatment of liquid, semi-solid and solid treatment in batch and continuous modes have been developed at that time.

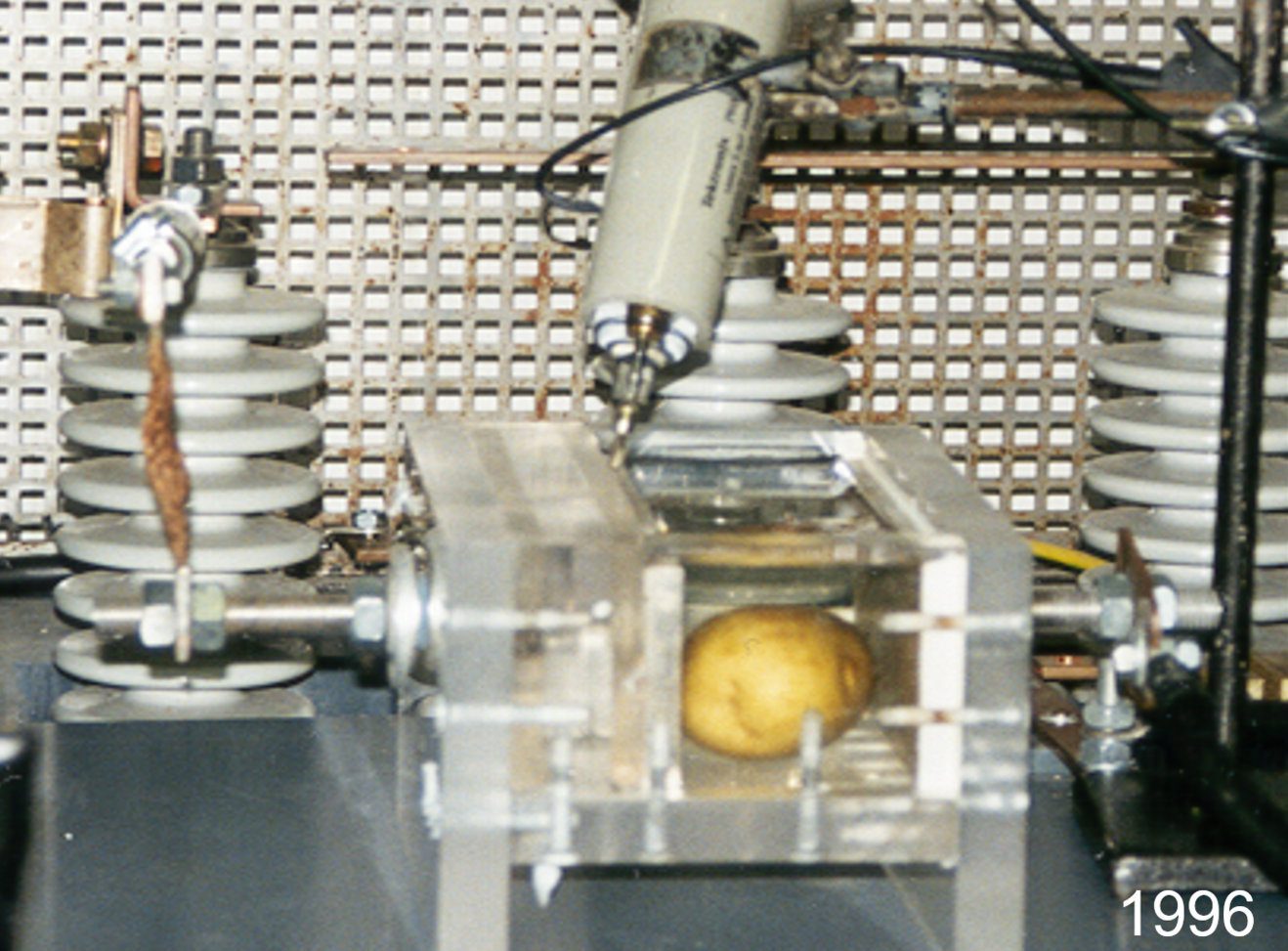

The images show PEF Pilot halls at TUB and at Thyssen Krupp.

PEF meets potato

The first papers on potato treatment have been published by Angersbach et al (1997). He suggested the use of PEF to accelerate drying of potato cubes as well as to improve starch extraction.

In 1997 the research group of Dietrich Knorr at TUB and a large-scale German starch processor started a BMBF Project, where pilot-scale equipment for potato processing was developed. Very similar results have been reported by Rastogi et al (1999) for carrot tissue as well as treatment of sugar beet (Esthiaghi and Knor 1999).

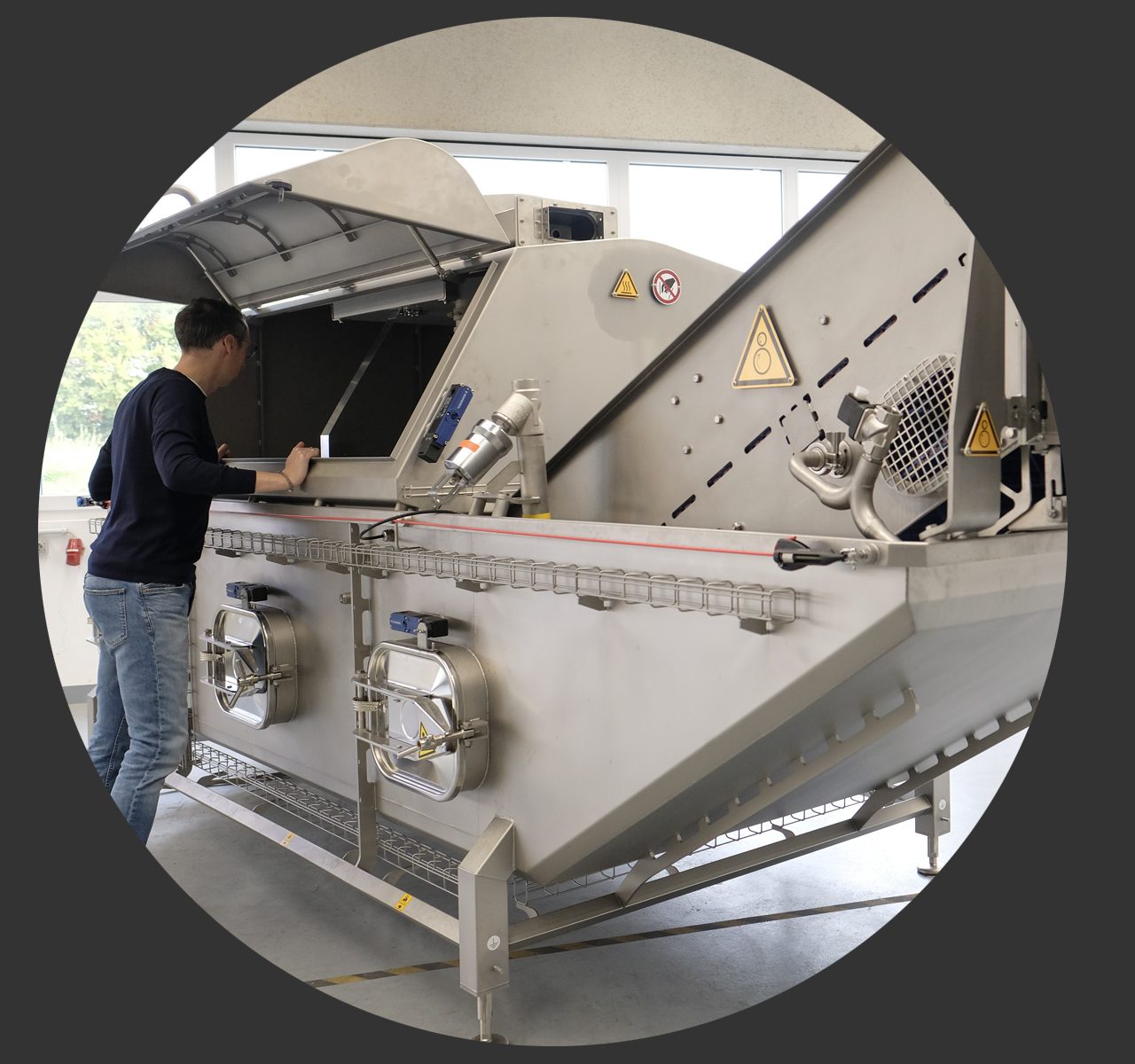

In 1998 technical scale systems have been developed for continuous PEF treatment of whole potatoes in the potato starch industry at TUB. Early designs used gravity as a transport means, but very fast it has become obvious that forced product transport is required and water wheel and conveyor belt systems have been tested in 1999. Making use of horizontal or vertical electrode configuration treatment belts have shown high process performance, reliability as well as cleanability.

Industrial scale prototype

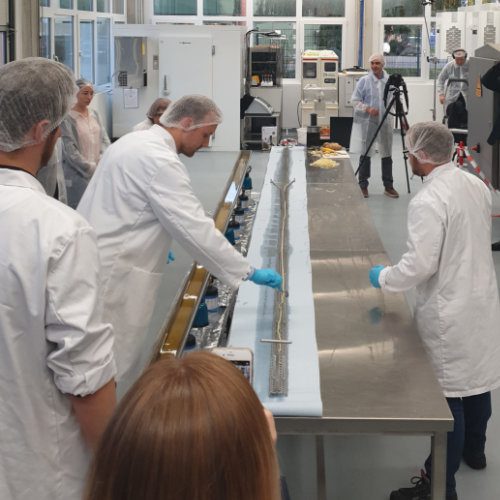

Based on the promising results at TUB, a team of engineers and scientists, including Dr.- Ing. Volker Heinz and Prof. Dr. Stefan Toepfl, started the development of turn-key, industrial PEF systems at the German Institute of Food Technologies (DIL e.V.) and in 2006 an industrial scale prototype was installed for French Fries processing.

The process has subsequently gained interest from a number of potato processors. In a joint project with Wernsing Feinkost GmbH, an industrial-scale unit went into developed in 2010 and then installed in 2012. Today that system is still currently operational (2023).

In 2009 Elea’s current MD Prof. Dr. Stefan Toepfl won the Georg Hahn prize for his doctoral thesis on PEF.

The beginning of Elea

The efforts paid off: in 2012 three further units have been installed in Wernsing production sites in Germany and Denmark. In the same year, Elea was founded as a spin-off entity and received a licence agreement for the production and distribution of PEF systems developed at DIL.

Under the leadership of Nick Speakman, Elea recruited its own experts for engineering, R&D and Sales and started the promotion of PEF systems to the potato industry.

In 2016, the Elea Team moved into a new building, just opposite the DIL facilities. The building is equipped with a bespoke office and a spacious pilot hall. With state-of-the-art equipment including an Elea PEF Pilot trial system, industrial processes like frying, cutting, drying or a comparison of thermal and PEF processes can easily be mimicked. In the following years, Elea was growing in business and as a company.

In 2017, the North American distributor Food Physics was established, and Professor Dr.-Ing Stefan Toepfl became Elea’s new Managing Director.

PEF Juice for Hoogesteger

In 2012, the first industrial Elea PEF system for liquids was installed at Hoogesteger in The Netherlands to extend the shelf life of fresh juices and smoothies. They call their PEF process FMP: fresh micro pulse.

50 Elea PEF systems installed worldwide

By 2017 the world was starting to wake up to the potential that PEF brings to the food and beverage industry. Elea now had more than 50 installations, both belt and pipe systems, installed all over the globe.

The world’s first all-in-one compact PEF belt system

In 2018, a PEF sustainability study with accurate data from our potato industry partners was released. The study demonstrated that by replacing conventional preheaters with PEF equipment, the energy requirements and water consumption can be hugely reduced by up to 90 %, followed by many additional benefits. (McHugh and Toepfl, 2016, Fauster et al., 2018).

Welcoming the world to Elea

To present PEF benefits to a broader audience, Elea devised its own PEF demonstration event. The first Elea PEF Advantage Days took place in Nov 2019 in our headquarters with PEF workshops and live demos. Leading international PEF experts provided lectures and insights, and our guests visited a running industrial PEF system at a nearby client. The Elea PEF Advantage Day is now a regular event in the Elea calendar.

PEF Pilot Dual

The Elea PEF Pilot Dual is the first modular PEF system to process liquid and solid foods.

Comprising of a core unit (designed primarily for pilot scale testing), the system is customisable with the addition of external plug-in units. These units are designed to service specific applications and increase the PEF Pilot’s processing capacity.

PEFinars – Elea’s application targeted live webinars

In 2021 and 2022, during the COVID pandemia, we kept in contact with our potential clients by developing online PEFinars: webinars with live demonstration of PEF treatments on applications like French fries, chips, fruits, vegetables and more. Some of the PEFinars were not only available in English, but also in Russian and Spanish.

Leading PEF supplier

In 2022, Elea is celebrated ist 10th anniversary. A lot has happened in the past few years. Back in 2012, the company started as a start-up with three employees, today it employs 30 professionals in different departments. Elea Technology has sold and installed around 250 systems worldwide and has become the leading technology supplier with a network of regional representatives and technology partners. The largest systems can process up to 100 tonnes of solids or 5000 litres of liquid per hour.

Development of new PEF applications and equipment is ongoing. So stay tuned.

The New Elea PEF Advantage B 1000-850

Elea introduces its new B1000-850 system design, the highest capacity belt system to date. With all safety features included in the belt vessel, the design enables processing of up to 100 t/h with a compact, easy-to-install footprint.

In addition to the B1000-850, Elea presented the new B100-535 system design and promoted upgrades on the B1 design, the PEF Pilot range and new process control options.

Extracting more from grapes and olives

Elea’s P1 PEF extraction system gained more interest in the wine and olive oil industry. We organised olive oil trials in Greece, Spain, Tunisia and Italy and wine processing in Spain, Italy, and the United States. -with each trial yielding exciting results

Elea R&D: projects, papers and patents

Elea PEF projects

We are involved in more than 30 national and international PEF research projects.

Elea PEF Patents

Currently, Elea owns more than 30 patents and patent applications.

Elea PEF papers

Elea Team members are authors of more than 30 scientific papers about PEF.

External PEF papers

More than 220 papers have been published with studies using an Elea PEF system.

Elea in the press and TV

In the last few years, public awareness of PEF’s transformative effect on food has slowly grown. Below are a few examples of how PEF was covered by the Media and how Elea helped shape that narrative.