EUROPEAN INDOOR TRADE EVENT FOR THE POTATO SECTOR

INTERPOM is the most specialised indoor trade fair for the potato sector in Europe where the whole chain is represented: from growing to processing and marketing with over 300 exhibitors from 15 countries and 19 500 visitors from 49 countries.

The exhibition offers a complete range of products and services for all professionals in the potato sector: growers, contractors, processors, packers, buyers and traders of fresh and processed potatoes from all corners of Europe – and increasingly, from other continents as well.

We are very happy to announce that Elea will be attending with a booth presenting 2 new system designs. Visit Elea in hall 2 at our booth No. 224, talk to our snack experts, taste our products and discover, what Elea Pulsed Electric Field can do to value your business.

Looking forward to meeting you there!

50 % discount with reduction code ELEA2022

The code ELEA2022 can be used several times and offers a 50% discount on the entrance fee (5 EUR instead of 10 EUR pp.)

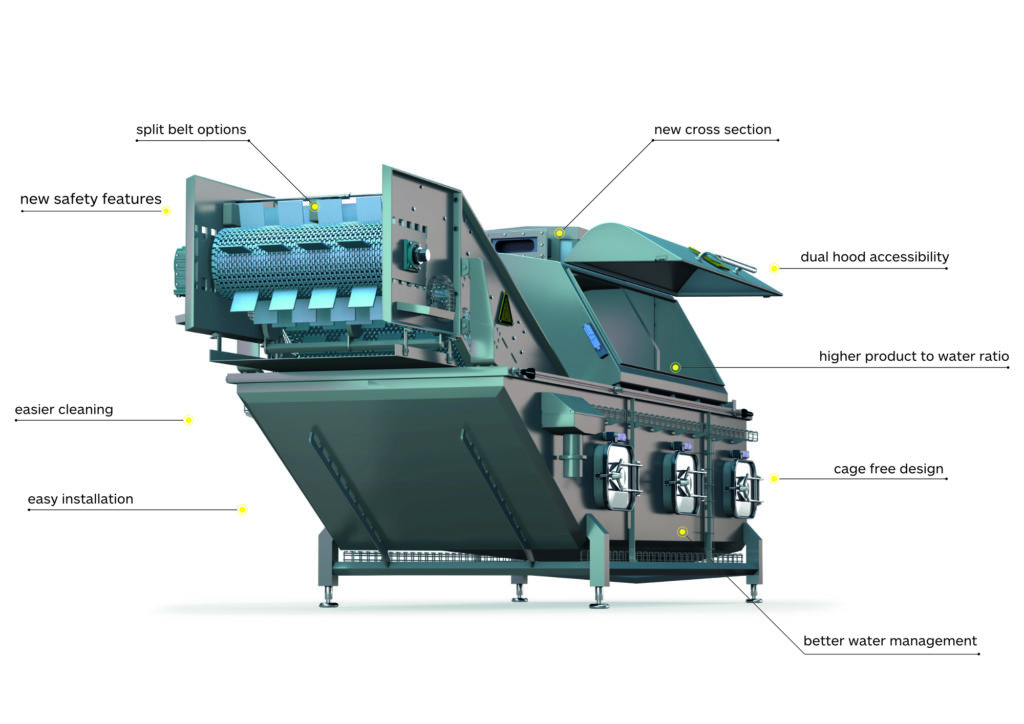

Elea introduces its new B1000-850 system design, the highest capacity belt system to date. With all safety features included in the belt vessel, the design enables processing of up to 100 t/h with a compact, easy-to-install footprint. The largest free cross-section on the market and optimized product in- and outfeed allow a high product-to-water ratio with only generator required.

Other new features include new pulsed power connections with extended cable length, a range of belt types with enhanced belt lifetime, integrated belt motoring, improved water management, and cleaning. The design is fully suitable for sinking and floating products.

Available options also include split belt options for multiple products, anti-foam dosing and automated conductivity control.

Stefan Toepfl, Managing Director at Elea: “Our team´s development work has focused on increasing capacity with reduced energy and water requirements. We have distilled ten years of experience, process know how and user feedback into the design, enabling our clients to process more for less.”

In addition to the B1000-850, Elea presents the new B100-535 system design and will promote upgrades on the B1 design, the PEF Pilot range and new process control options.