Monitor quality control with precision and optimise treatment conditions for potato and vegetable cutting with Elea Cut Control.

Developed to measure the cutting force in roots, tubers and vegetables both before and after PEF treatments, Elea’s Cut Control is an important tool when it comes to product quality control.

Designed and built with the same care, quality and technical expertise as our other systems, it’s the ideal addition to understand and enhance the benefits of PEF treatment.

By pushing the raw produce through a grid pneumatically, the Cut Control is able to measure the cutting force and display the results instantly to help identify seasonal variation and develop optimum PEF treatment conditions.

The Cut Control system is an industry-ready measurement unit that’s ideal for use in a quality control lab, yet it’s also portable to allow direct operation right at the heart of the production line. Delivered with a handy storage and transport case, the system also comes with two cutting grids and a sample preparation grid as standard.

Elea’s Cut Control

CutControl

15 kg (25 kg with transport case)

Device 610 x 240 x 210 mm (LxWxH). Case 710 x 310 x 350 mm (LxWxH)

Frame and cutting grids are stainless steel/anodised aluminium. Pusher for products is white PE.

Maximum 730 Newtons.

6×6; 8×8; 10×10; 13×13 mm.

Services required

ELEA’S CUT CONTROL

Full crop, cutting and quality control with the PEF Advantage Belt system and Elea Cut Control

INSTANT TEST RESULTS

Identify seasonal variations and effects quickly and easily so you can select the optimum PEF treatment conditions.

The Elea Cut Control measures the cutting force of a wide range of tubers such as potatoes, sweet potatoes or cassava before and after PEF treatment then displays the results instantly.

FLEXIBLE PROCESS ADJUSTMENT

PEF treatment using the PEF Advantage Belt system gets rid of seasonal variation in raw produce firmness to provide an even and consistent cut throughout the year.

The PEF treatment intensity can be easily monitored with the Cut Control to identify the ideal parameters for the best possible product yield, quality and flexibility.

PORTABLE AND ROBUST

Elea’s Cut Control is more cost-effective than a texture analyser and doesn’t need an extra computer to display results. Its robustness and portability make it the perfect device for PEF Advantage Belt system process control in an industrial production line.

The device comes with a range of cutting grids, sample preparation grid and a handy transport case too.

USING CUT CONTROL WITH OUR PEF ADVANTAGE BELT SYSTEMS

Reduce feathering, knife wear and oil uptake to enhance product quality.

PNEUMATIC PRESSURE SENSOR

The pneumatic pressure sensor helps to identify the optimum PEF treatment intensity and recommend the best parameters to achieve exceptional product yield, quality and flexibility. This can then be kept consistent throughout the production process.

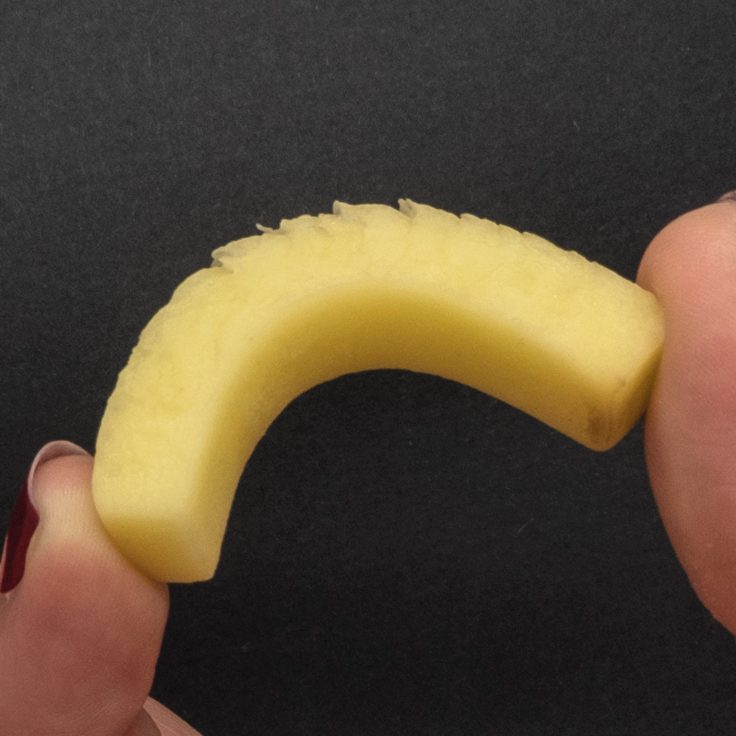

UNTREATED CUT POTATO STRIP

These potato strips have been cut using a hydro jet cutter, a more traditional method of cutting, and are then more prone to feathering. This is because instead of a clean cut, the tissue is broken and torn apart.

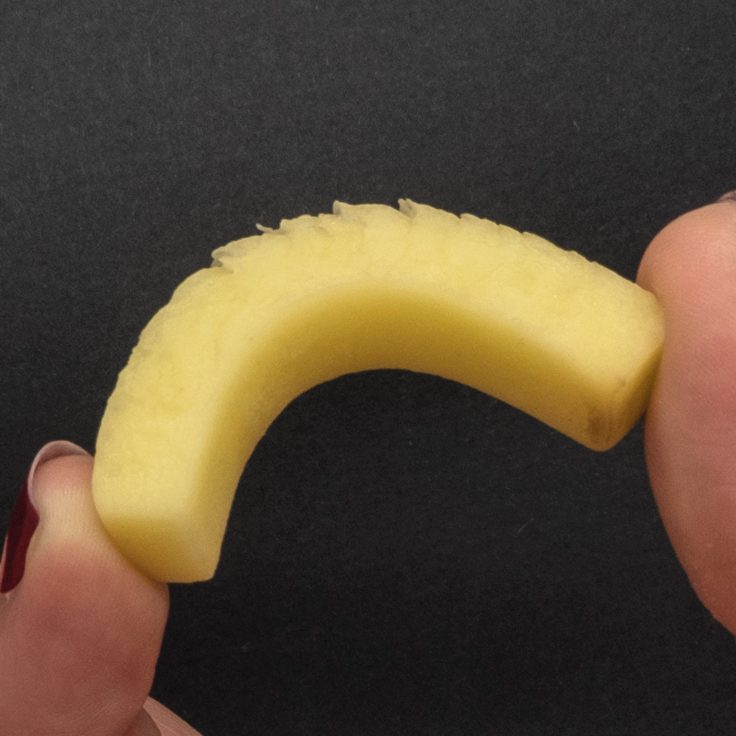

PEF TREATED SWEET POTATO

Alternatively, these sweet potato strips have been treated with PEF and now we’re able to achieve a smooth cut. This is a true example of the benefits of PEF, which leads to longer fries, reduced oil uptake, overall better browning and less knife wear too.

PEF works at a low energy input (~1 kJ/kg), by inducing small pores in the cell membrane resulting in a loss of turgor pressure and tissue softness, allowing for a smoother cut.

When using traditional methods of cutting such as a hydro jet, there’s substantial feathering as the tissue is more broken than cut. After PEF treatment, the feathering is significantly reduced and the cut is smooth. This creates opportunities for longer fries, reduced oil uptake during deep-frying and less knife wear.

As the energy level increases, pore size does too, which is why the intensity needs to be monitored by the Cut Control and the most suitable parameters for optimum process and performance yield need to be pinpointed to ensure that no undesired solids or yield losses occur.

In chips and fries processing, the Elea Cut Control allows our clients to develop the optimum treatment conditions for different potato varieties, as well as identifying seasonal variations and effects.