Development of an acoustic and AI driven inline quality control solution for PEF efficiency.

PEF SWITCH

Development of a PEF Switch for alternating PEF utilization at multiple food production lines.

Collaborating with external specialists in various research fields guarantees the best outcome of a project and builds a reliable research network.

New Pulsed Electric Field opportunities and innovations are often driven by our collaborative R&D projects. The knowledge gained from this research is directly funnelled into new PEF solutions and applications via the Elea PEF Advantage™ Belt and PEF Advantage™ Pipe systems.

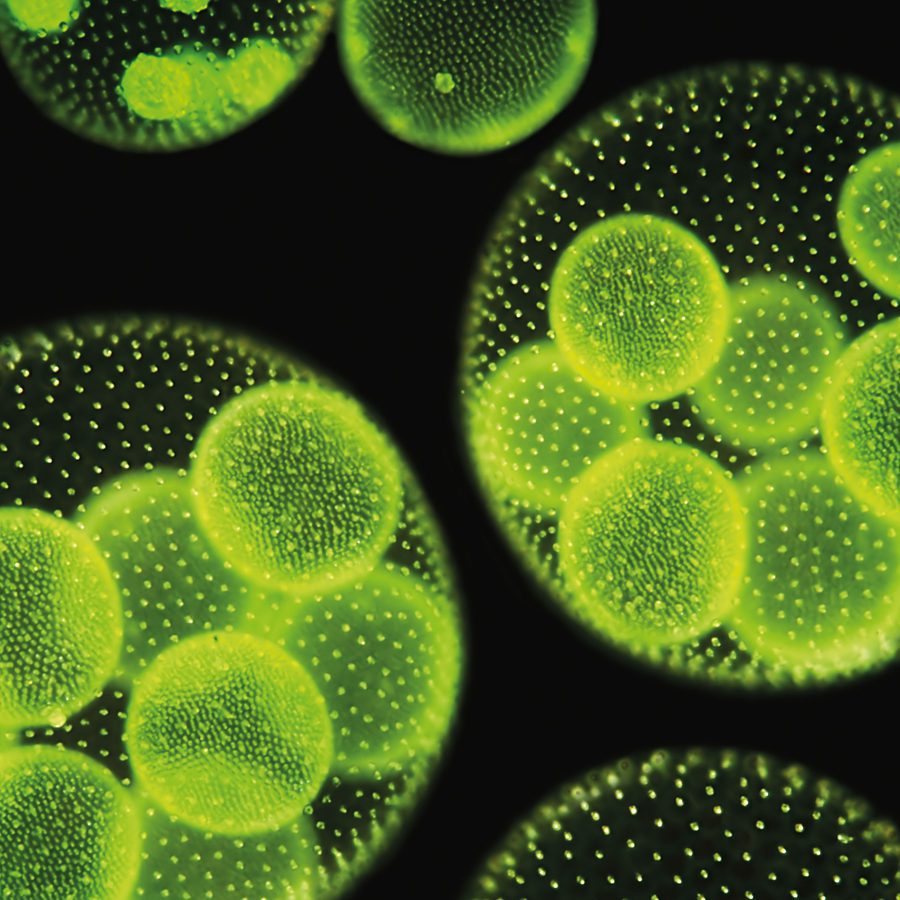

Elea is currently involved in a wide range of PEF collaborative research projects including stimulation of algae for improved growth and extraction, PEF drying optimization for improved quality and form stability and new improvements for meat processing.

Elea has built a valuable network of research partners from both academic and industry backgrounds from all over the globe.

These include research institutes such as DIL and FEI, and universities such as the University of Applied Science of Osnabrück, University Vienna BOKU, CPUT in South Africa and the Warsaw University Of Life Sciences in Poland.

OUR EXPERTISE

WE ARE THE WORLDS LEADING EXPERTS ON PEF

Pulsed Electric Field research and development is at the core of our offering. Each member of the Elea R&D team has deep knowledge in PEF processing and nearly half of our Elea staff work in the research and developments department.

Whilst working with DIL and in collaboration with German fries manufacturer Wernsing, Elea’s Managing Director, Prof. Dr. Stefan Töpfl, developed the first industrial scale PEF system for potato processing.

Since then we are specialised in PEF technology to establish industrial processing solutions. Elea’s

research projects are adding constantly to our knowledge base and system expertise.

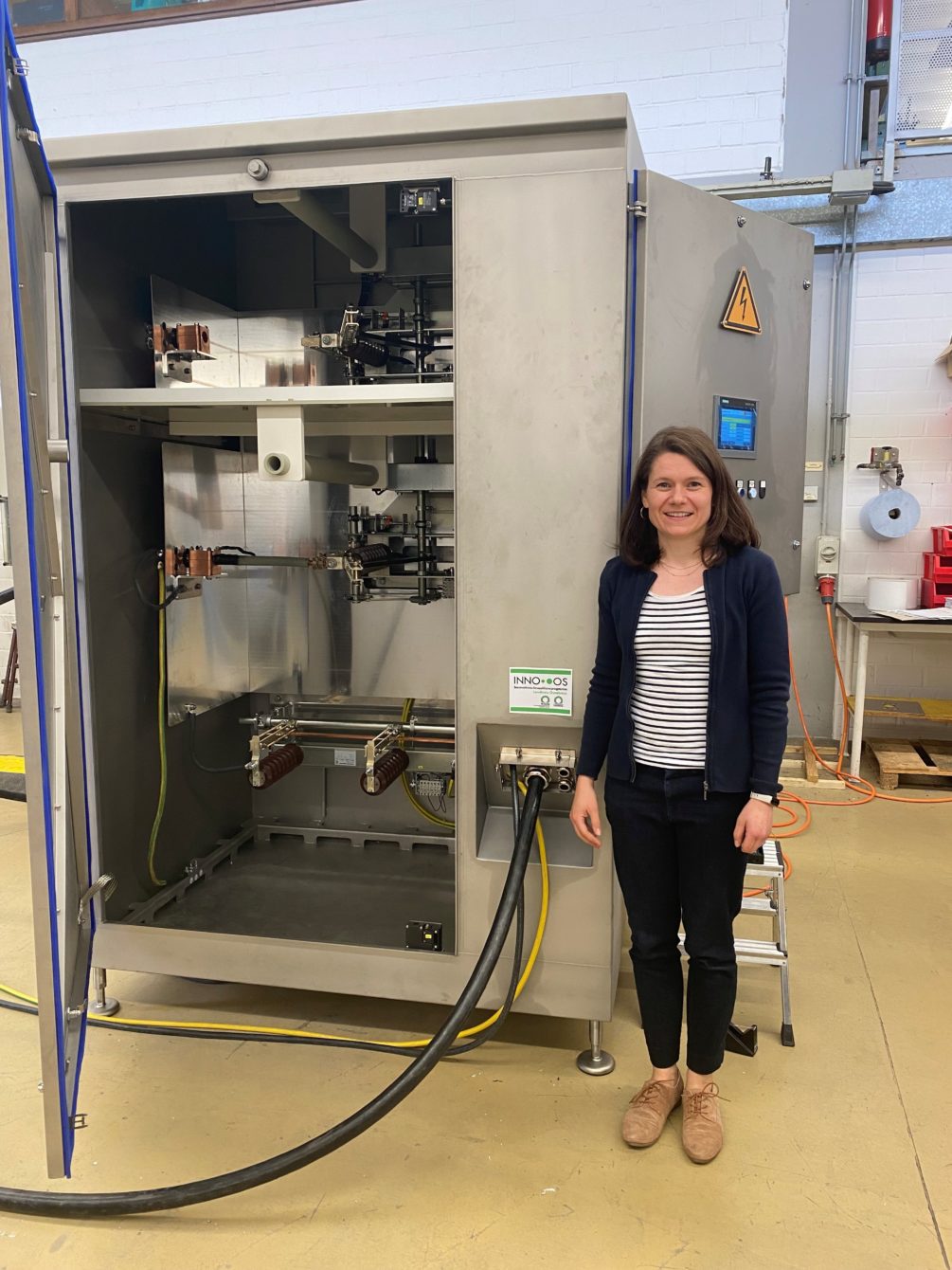

The core apparatus to many of our lab or pilot scale research projects are the Elea PEFPilot system and our liquid testing system. Enabling us to develop new products and services in conjunction with our research partners. The results gained at smaller volumes with the PEFPilot is then up-scalable to our PEF Advantage™ Belt and Pipe systems.

ELEA PILOT HALL FACILITIES

CUSTOM BUILT FOR PULSED ELECTRIC FIELD RESEARCH, DEVELOPMENT AND COLLABORATION

Our custom-built pilot hall in Quakenbrück is fully equipped with state-of-the-art devices to emulate your production process. Here we develop new applications and opportunities for PEF and are able to mirror industrial processes. Every PEF solution we develop is customizable and then up-scalable to a production line.

No one is better placed to help trial your product with Pulsed Electric Field. Elea offers trialling and expertise in our pilot hall on daily or weekly rates. We can also place our PEF systems in your production line for onsite-trials.

Examples of the Pulsed Electric Field studies carried out in the pilot hall include:

Process savings and improvement of your frying process for snacks, optimisation studies using our professional fryers to mimic typical frying curves.

Developing new cuts and novel snack shapes, measuring cutting force reduction.

Liquid shelf life study with our continuous liquid PEF system.

Drying optimisation using PEF to improve rehydration, quality and form stability.

PEF stimulation of algae to enhance growth and extraction values.

To name just a few.

This is be completed using our wide range of analysis equipment, good collaboration with local laboratories and the huge additional analytical capacity at our neighbouring laboratories of the German Institute of Food Technologies (DIL).

OUR R&D PARTNERS

TO BUILD STRONG RESEARCH RELATIONSHIPS AND SHARING RESOURCES

We always work in close partnership with our clients to assure that they get the best PEF benefits for their product.

To share our expertise, we are collaborating with a number of partners, from research institutes such as DIL and FEI to Universities such as the University of Applied Science of Osnabrück here in Germany, University Vienna BOKU, CPUT in South

Africa or Warsaw University Of Life Sciences in Poland.

On top of that, we work in close relationship with industrial R&D centres from clients or other innovations companies to solve real-world business challenges and to generate an industry database.