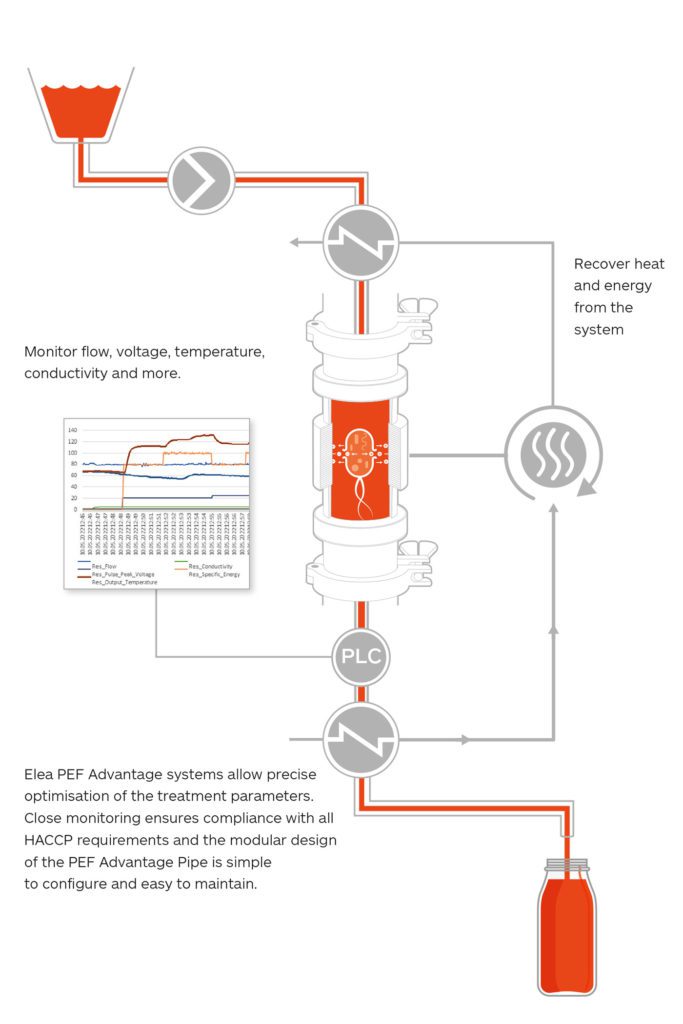

The Elea PEF Advantage P 10-100

Up to 20 t/h for extraction and 2.500 liter/h for shelf life extension of liquids, subject to process requirements. Hygienic integrated design CIP, SIP ready.

Complete control of process parameters and online monitoring dose to comply with all HACCP requirements. Its modular design is easy to install, configure and maintain.