We design, build and install a broad range of medium to high-capacity systems customisable to your needs. PEF benefits include greater yield, improved quality, oil and energy savings, and exciting opportunities for new snack products.

The Elea Pulsed Electric Field Advantage Belt systems are the ideal solution for treating tubers, roots, vegetables and fruits and are available in a range of models – B 1, 10, 100, 1000 and our latest, the B 1000-850

Our PEF Advantage Belt system has been used throughout the potato-processing industry since 2010 and our PEF technology pre-treatment has become the standard worldwide due to its dramatic and positive changes to both product and process.

The Elea PEF Advantage Belt system is an energy-saving low-temperature process that replaces the need for blanching potatoes and other produce before cutting. As well as reducing energy and water consumption by up to 90%, the PEF Advantage Belt system is a volumetric treatment, so you can expect treatment uniformity, no matter the item of fresh produce.

This uniform softening means that a smooth cut can be achieved. French fries and chips achieve longer shapes, become more pliable and

experience less breakage, ultimately leading to opportunities for more extreme snack shapes. What’s more, during deep-frying 10% less oil is absorbed and browning becomes more even for a brighter, more appetising colour.

Drying processes for the production of dried fruit and vegetables can be enhanced too. The pre-treatment of food with the PEF Advantage Belt system leads to a greater diffusion coefficient which greatly improves the drying process in both temperature and time. This leads to energy savings and better shape, colour and overall quality of the dried products.

Elea PEF Advantage B 10, 100, 1000

Pulse Generator

Dependent on system, stainless steel cabinet.

Continuous Treatment Belt

Up to 100 t/h of potato in a potato-water mixture

Automated level control, overflow channel, automated drain valve, water conductivity and temperature measurement.

Stainless steel.

Dependent on system, belt should be attached to generator.

Services Required

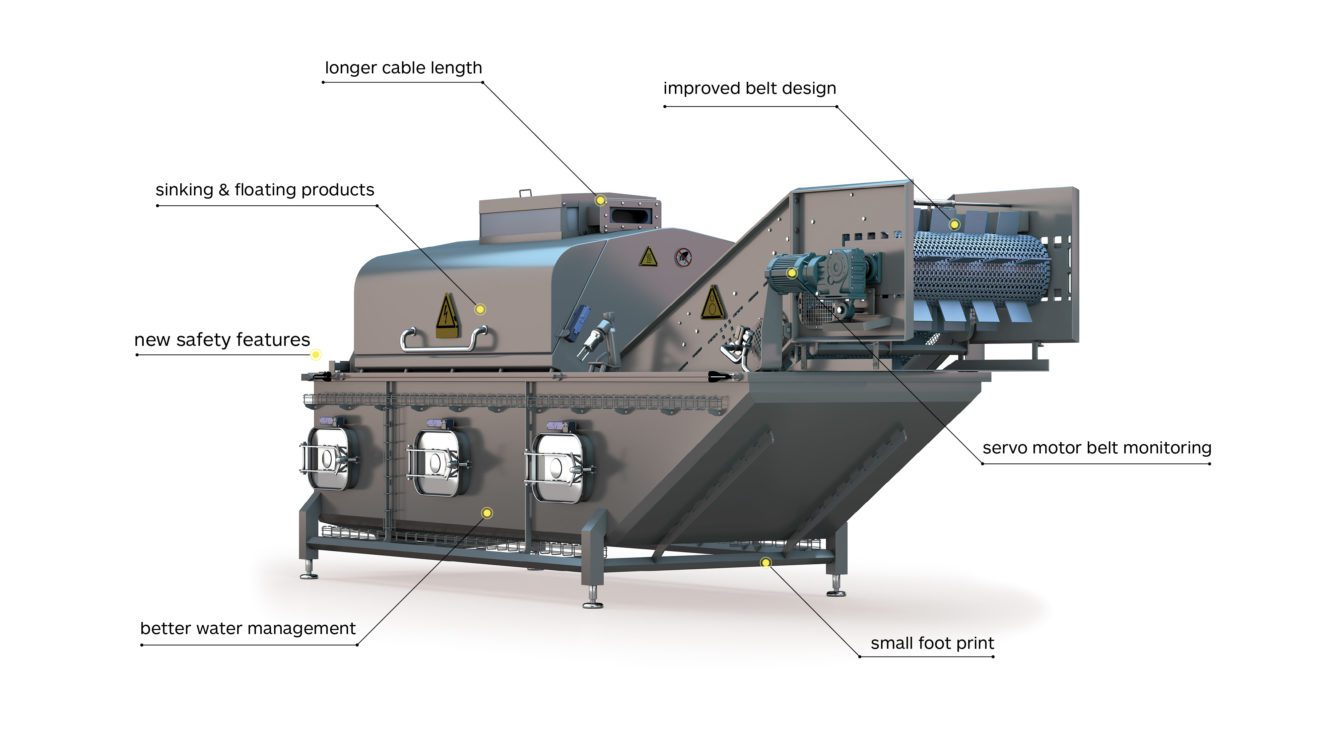

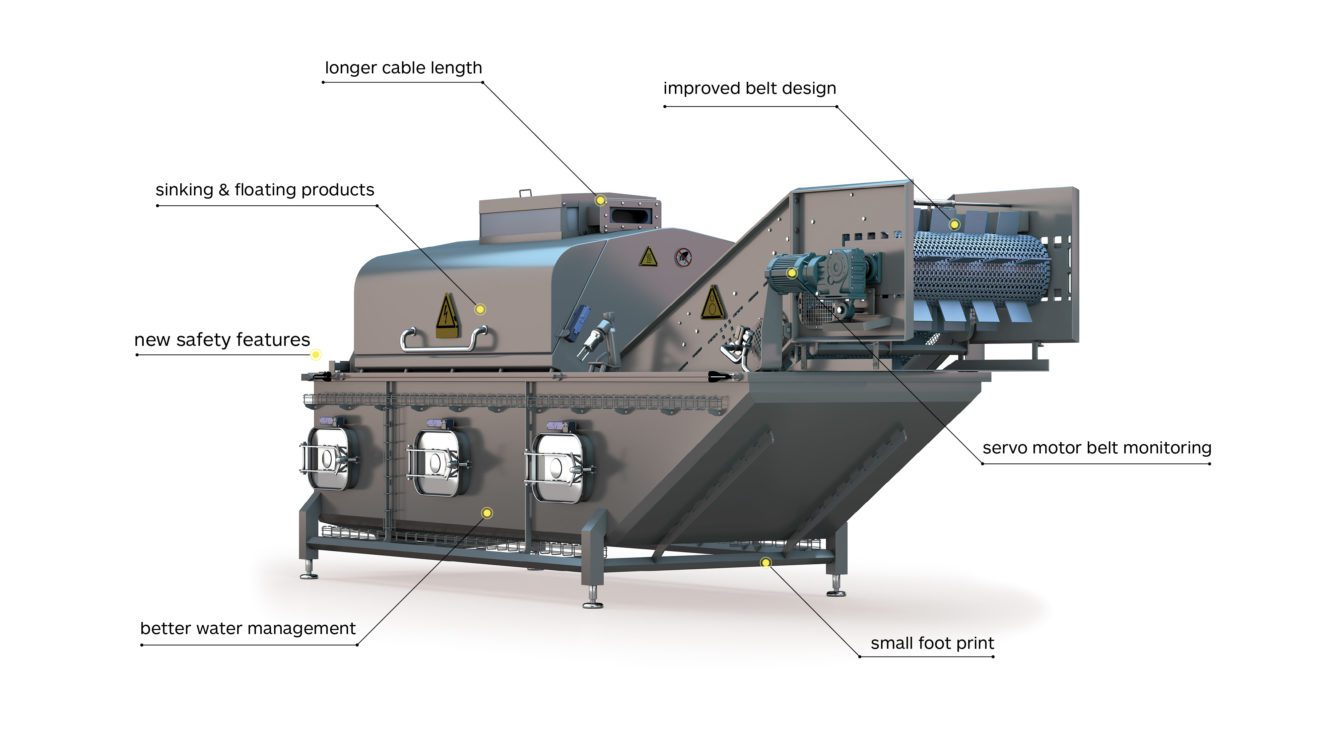

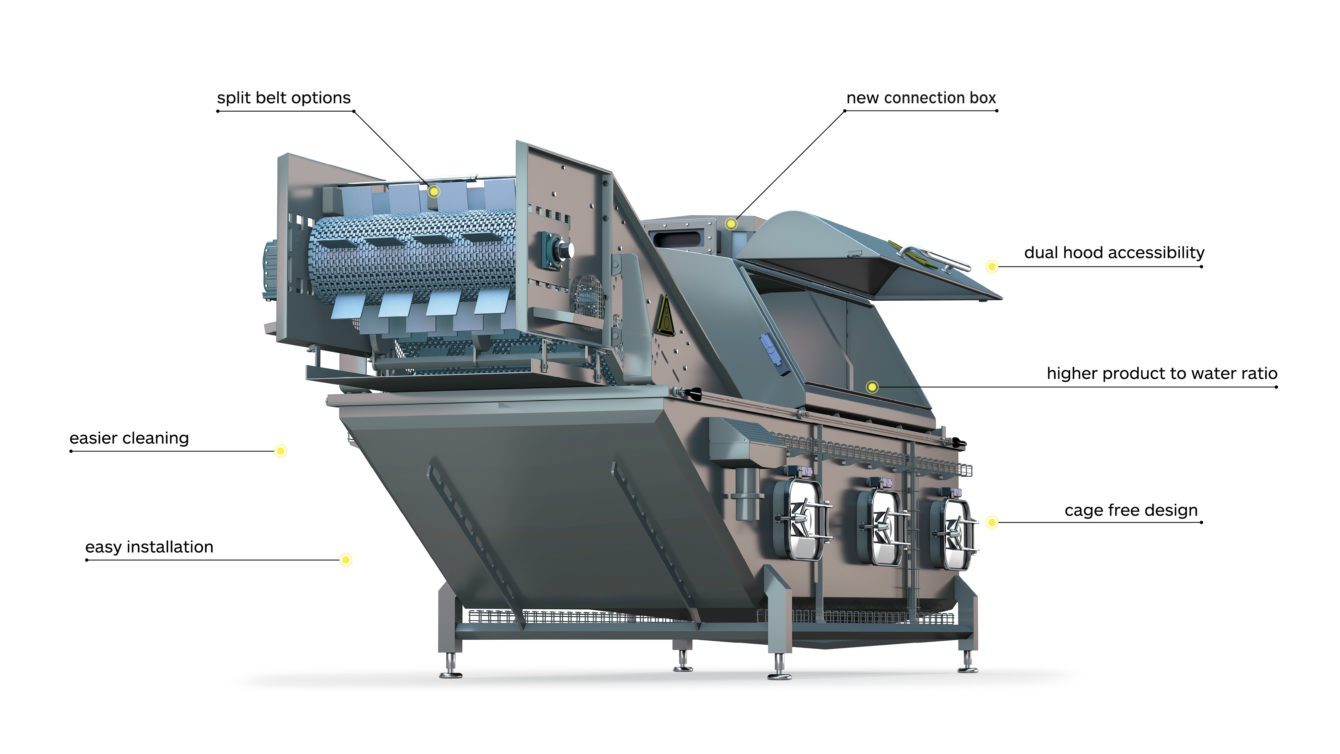

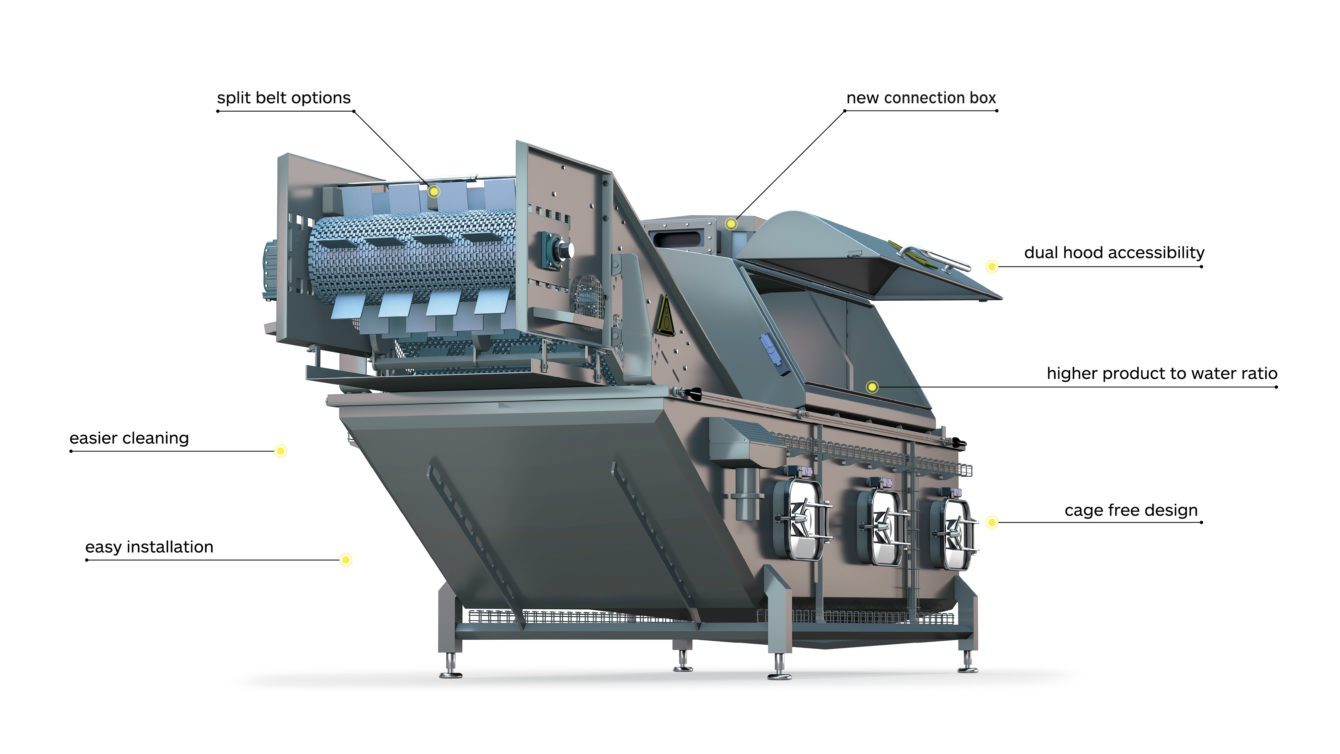

Introducing the new Elea PEF Advantage B 1000-850, our biggest, most innovative system to date

Capable of processing up to 100 t/h,

enabling you to process more for less

Contact us to discuss which PEF Advantage Belt system is best for you.

Looking for another type of PEF system?

We provide PEF solutions throughout the food, beverage and scientific sectors

For capacity requirements of 0-7.5 t/h, we offer the PEF Advantage B 1 and B 1 mini. For pilot testing and smaller production needs, we have the versatile PEF Pilot Dual. If you are looking to treat liquids or liquid food we have our PEF Advantage Pipe systems

Advantage B 1 & B 1 mini

Perfect for drying, chip production, and vegetable processing all-in-one system easily integrates into any production line.

PEF Pilot Dual

The world’s only fully modular and configurable PEF solution for producing and testing liquid and solid foods.

Advantage Pipe

Inactivate microorganisms and improve extraction for beverages and liquid foods continuously at low temperatures.

All Elea systems are designed and manufactured by us in Germany

We manufacture each of our PEF Advantage Belt systems in Quakenbrück, Germany. They’re designed, engineered and built by experts in PEF to the highest specifications.

24/7 Operation

Robust build and solid-state typology ensure that the Elea technology in our PEF Advantage Belt systems is exceptionally reliable, which means 24/7 operation and low maintenance costs.

Our PEF Advantage Belt systems are manufactured to the highest quality to make sure each one can withstand continuous operation and maximum performance. As part of our range of service contracts, we can supply each customer with around-the-clock technical support.

Fully Customisable

To fulfil the needs of our clients, we’ve made sure our PEF Advantage Belt systems are fully customisable and scalable to specified criteria across design, mechanics and software programming.

Our expert team works in close collaboration with our clients to make sure that the system we deliver meets their requirements, so even if you need something like a split belt, we can make it happen.

Total Control

Our PEF Advantage Belt systems are designed to be compatible with any standard processing control system and fully accredited and certified for regional installation anywhere in the world.

We work in partnership with our clients to make sure they’re using the full potential of their PEF Advantage Belt system and getting the most benefits of PEF. We’ll listen to what suits your product and desired application goal and help to achieve that with a tailored treatment parameter.

Do we need a full-time operator for our PEF Advantage Belt system?

No. There’s no need, we design our PEF Advantage Belt system to be run without a full-time operator.

What maintenance is required for the PEF Advantage Belt system?

We recommend that each year your PEF Advantage Belt system received an annual inspection from the Elea service team. They’ll check the system’s calibration and correct function, along with mechanical checks. There are few parts on a SmoothCut™ system that are likely to experience wear, and we make continual steps to reduce our low maintenance costs even further. We do recommend that customers give their SmoothCut™ system a monthly PPM that takes approximately one hour.

Are all the parts that come into contact with the product food grade?

Yes, each part of the PEF Advantage Belt system that comes into contact with the product is either stainless steel or CE and FDA listed plastics. All certification is supplied with your system as part of the documentation.

Are the metal parts of the PEF Advantage Belt system passivated?

Yes. We manufacture all metal parts from Stainless Steel 1.4301 or higher. All metal parts of the PEF Advantage Belt system are grit polished after welding.

Can I control the PEF Advantage Belt system remotely and download data?

Yes. We can link to any factory Scada system and allow full access to our PLC and controls as if you were standing next to your PEF Advantage Belt system. Additionally, if required we can log in from our office to assist with any issues.

Is it difficult to replace any PEF Advantage Belt system parts if they fail?

No. Our PEF Advantage Belt system is designed for quick and easy replacement of parts. Any electronic parts are plug and go with no additional set up required.

Are there any special cleaning requirements for the PEF Advantage Belt system?

No. We ensure that each PEF Advantage Belt system has easy access for cleaning and have no special requirements regarding cleaning solutions that are typically used in the food industry.

What utilities are needed for the PEF Advantage Belt system?

Your PEF Advantage Belt system will require electric, compressed air, water and cooling water for the generator.

Do Elea offer training for PEF Advantage Belt operators and maintenance personnel?

Yes. During the installation of your PEF Advantage Belt system, we carry out training for operators and maintenance personnel as standard and can also offer further training at our facility in Quakenbrück, Germany. All training is tailored to your SmoothCut™ system and copies of the training material is provided for all participants.

Can the PEF Advantage Belt system work with floating products?

Yes, absolutely. We can fit your PEF Advantage Belt system with an additional top belt (or hold down belt), to keep floating products submerged. If this is something you think you require after initial installation then it can also be retrofitted too.

How many water changes are needed in the PEF Advantage Belt treatment tank in a 24-hour period?

Typically, your PEF Advantage Belt system will need between 4 to 6 changes during a 24-hour period – although this will be determined by the product volume and the cleanliness of the product. Your SmoothCut™ system will monitor and control the water conductivity automatically, so can periodically drain small amounts of water from the tank, and replace with clean, fresh water.

Are all the electrical cabinets suitable for placing in wet areas?

Yes. The electrical cabinets found on the PEF Advantage Belt system are designed for wet areas.

Can I use a closed loop water chiller to supply cooling for the PEF Advantage Belt generators?

Yes. Some of our customers prefer to use a closed loop cooling circuit for their PEF Advantage Belt system generators using water or glycol that typically run with a minimum temperature of 15°C.

Will the PEF Advantage Belt system treat my whole product evenly?

Yes. It is a volumetric method and as a physical process, PEF will be able to treat the products uniformly. For example, all potatoes introduced to PEF in the water tank, or juice in the treatment cell will be affected.

Training, global support and intallation

Our highly skilled technical team provide comprehensive training and a continual support service around the world, including full PEF Advantage Belt system installation and maintenance.

TRAINING

Investment in training of your PEF Advantage Belt maintenance engineers and operators will ultimately result in skilled and knowledgeable personnel. This will allow for ideal system operation and performance when it comes to yield, settings, up-time and safety.

Experienced and well-trained staff are essential to your success, so we offer in-house and on-site PEF Advantage Belt system training that’s tailored to your specific requirements.

SUPPORT OPTIONS

We offer a number of service options that include full support, no matter where our clients are based, and will send a highly skilled technical team to provide full installation and maintenance when needed.

We can also conduct remote monitoring of your PEF Advantage Belt system and provide customer care around the clock. It’s also possible to connect to your system remotely, to allow diagnostic and support by our Customer Service department.

MAINTENANCE

Our proactive and preventative maintenance programme can be tailored to your PEF Advantage Belt system, so you can concentrate on creating and developing new ideas.

Production up-time is maximised by conducting inspections alongside a proper maintenance schedule and the replacement of PEF Advantage Belt parts if necessary.

Elea Cut Control and PEF Control.

PEF monitoring and optimisation tools

Optimise and maintain your PEF treatment parameters, get the best possible result for your product

Cut Control

Monitor quality control with precision and optimise treatment conditions for potato and vegetable cutting with Elea Cut Control.

PEF Control

PEF Control measures the impact of PEF cell disintegration and optimises mass transport processes, such as sugar extraction, drying or infusion.

Meet the Elea belt systems team

Kevin Hill

Jimmy Kinsella