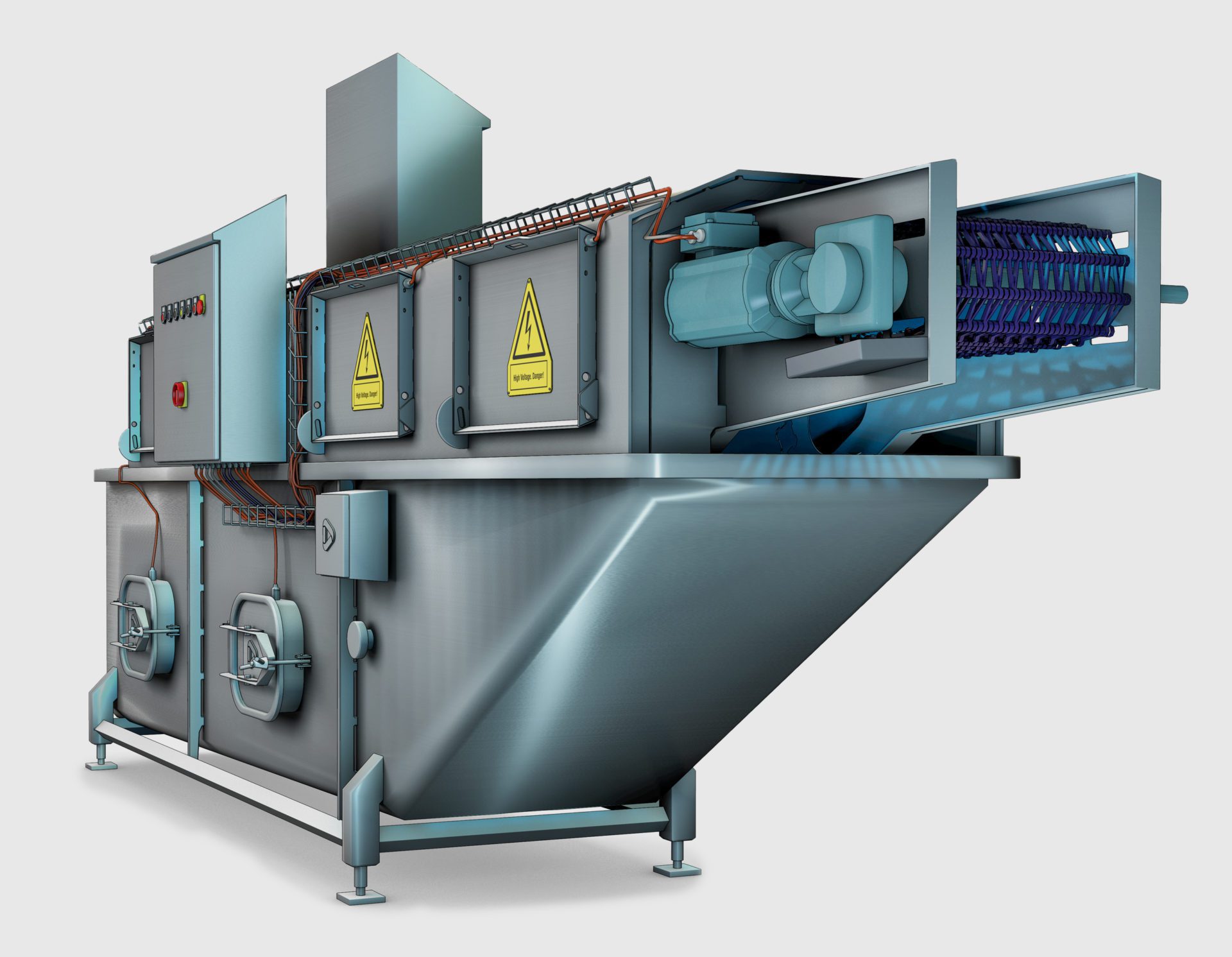

PEF Advantage B 1 & B 1 mini

The compact industrial-scale systems for the treatment of vegetables, tubers and fruits. The PEF Advantage B 1 & B 1 mini-systems are built as a single unit including a pulse generator, treatment belt and vessel. The B 1 is designed for treatment capacities up to 7.5 t/h.

The B 1 mini is specially engineered for smaller lines with treatment capacities of up to 3 t/h, with an option to upgrade to B 1 capacity if required.