Elea PEF Advantage Demo Days 2019

Elea would like to extend a warm thank you to all those who participated in our 1st ever Elea PEF Advantage event, three days of talks, insights and demonstrations about Pulsed Electric Field in the food industry with the added bonus of a world record attempt.

Elea, the market leader in Pulsed Electric Field (PEF) systems for the food industry, hosted the event at their headquarters in Quakenbrueck, Germany.

Experts and PEF users from around the globe came and presented insightful talks on PEF, on diverse topics ranging from exciting new applications for wine, PEF processing in the chip industry, sustainability benefits of PEF, PEF processing benefits and opportunities for Juice and many more.

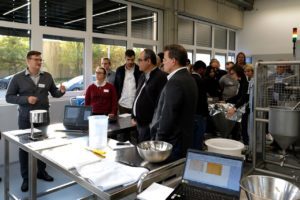

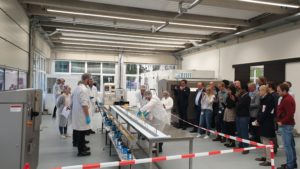

Elea R&D and engineering staff gave live demos including juice and snacks processing, drying and extraction improvement as well as a demonstration of industrial-scale systems and process monitoring options. Product samples have been manufactured and tasted by the participants.

On the second day of the event (in front of a large and enthusiastic crowd) Elea attempted to fry the world longest French fry. Cut in one piece from a single potato and reaching 314cm in length the world record attempt was conceived as a way of demonstrating PEF’s remarkable and transformative effects on food. Afterwards, another attempt was made with a sweet potato with even greater results reaching 347 cm.

Both attempts were only made possible by PEF, we are now waiting for the attempts to be ratified but we are confident.

The event highlighted Elea PEF benefits in various industry sectors, including reduced energy and water usage and well as improved product quality.

PEF expert talks

Elea has invited world-leading experts to present the latest developments and current research activities.

• Stefan Toepfl, Managing Director of Elea has given an overview of current and future PEF applications in the food and biobased processing industry. Currently, more than 130 industrial-scale PEF systems are installed, mainly in potato and juice processing but current research and application development is broadening the scope of applications towards other products such as dairy, pulses and nuts, tea as well as algae.

• Jimmy Kinsella, Engineering Manager of Elea has introduced the range of Elea PEF Advantage systems for solid and liquid products, including the all-new PEF Advantage Pipe One small scale liquids system and PEF Pilot Dual, a versatile unit for R&D and test setups. His talk has been followed by a discussion on technical and operator training requirements.

• Sergiy Smetana, Head of the Food Data Group at DIL, has presented on sustainability impact of PEF use in potato and juice industry. By life cycle analysis a 90 % saving potential for thermal energy and water-saving in comparison to conventional preheating has been shown for French Fries processing. In the juice industry the benefit of the technique has been found in producing premium quality products at low energy requirement and reduced retail waste.

• Brian Mayer, Process Specialist at Tayto has discussed benefits of PEF after implementation into their Scunthorpe facility producing potato chips. Elea PEF use resulted in improved slicing and a yield increase of 1 – 2 %, a 10 % reduced oil uptake. Reduced starch losses make the product more crunchy, lower frying time and temperature allow better product colour and quality.

• Javier Raso, Professor at the University of Zaragoza, has presented on public-funded and industrial projects in the area of wine processing. Increased extraction of anthocyanins and polyphenols, ageing on lees and fermentation control have been shown to be commercially viable PEF applications in that industry sector. At present, an industrial-scale test is conducted in cooperation of Elea and Zaragoza University.

• Jim Gratzek of Food Physics presented ongoing research work on validation of PEF use in the juice industry with a focus on the North American market. PEF has shown to result in superior product quality, dependent on treatment intensity product shelf live ranges from 4 – 12 weeks. Studies are performed on inactivation of relevant pathogens and surrogates. For juice HACCP/HARPC process monitoring options are available.

• Kemal Aganovic, Advanced Research Manager at DIL has given an overview of upcoming process options as a tool for product development. Current research activities of DIL include use of electric field based technologies, static or dynamic pressure use or process automation. DIL is available to Elea and its clients as a research partner and toll processing centre.

Demo activities

Elea PEF experts have set up six different demo activities allowing the participants to receive hands-on experience. The snacks demo has shown the potential to improve the cutting of potato and vegetable chips after PEF treatment and its potential to increase product yield and quality. In the juice pilot hall, PEF processed juices have been manufactured and evaluated. PEF has a significant impact on drying time and quality of (freeze) dried products – the demo has shown product samples and application ideas for snacks or dairy products. Elea has developed two process monitoring tools, Cut Control for characterizing PEF impact on textural and cutting properties and PEF Control to measure cell disintegration and release of intracellular liquids. In Elea´s equipment showroom, the range of Elea PEF Advantage systems has been exhibited.

Making plant cell electroporation and PEF impact on product structure visible the demos have shown the real-life application potential of Elea PEF technology. The discussions with participants have resulted in a number of new application ideas which the Elea team will follow up in cooperation with our clients and partners. For those who could not make it please get in contact to arrange for your test opportunity.