PROMISING RESULTS IN INDUSTRIAL TRIALS

Faster processing with energy and water consumption and a better quality product

Elea has been doing several trials in olive oil and wine production. We have been in olive mills in Greek, Spain, Tunisia and Italy to run a PEF system during the production of olive oil. For trials in wine processing lines, we have been to Spain, Italy and the United States. The results have been very positive and the interest in PEF use for extraction applications is growing.

PEF use in olive oil production

The technology of Pulsed Electric Fields is a low-temperature process and induces electroporation by gently opening the pores in the olive’s cell membrane. It is applied directly after crushing the olives, providing many benefits for olive oil, including improving early-season EVOO processing, increasing yield, and enhancing oil quality. With PEF, a yield increase of up to 10% can be achieved.

PEF lowers the temperature required for malaxation resulting in a significant increase in the amount EVOO gained. Malaxation time is also reduced, enabling greater processing capacity. The extraction of the oil will be improved by opening pores in the olive cell membrane. It is a low-temperature process, reliable and instantaneous, and can be applied continuously 24 hours a day.

PEF maintains and can improve the quality of the olive oil. Our HPLC study has shown that the number of biophenols in the EVOO is increased by 9-18% due to the PEF treatment.

We can illustrate the cost-benefit of PEF with a simple calculation. PEF treatment can potentially increase the oil yield from 20 to 22.7%. In an industrial oil mill operating at 160 t/day, PEF treatment could increase the EVOO daily production by 4.33 t (from 32 to 36.33 t). Let’s assume an EVOO price of 2-4 €/kg; this results in a potential extra turnover of between € 8,660 & € 17,320 per production day.

PEF use in wine production

PEF, as a low-temperature method, replaces other heat extraction treatments, such as thermovinification. Less heat in every stage of the winemaking process allows for retaining far more natural flavours from the grape and higher colour intensity. PEF gives more flexibility in harvest by getting more value from all grapes and opens new product opportunities.

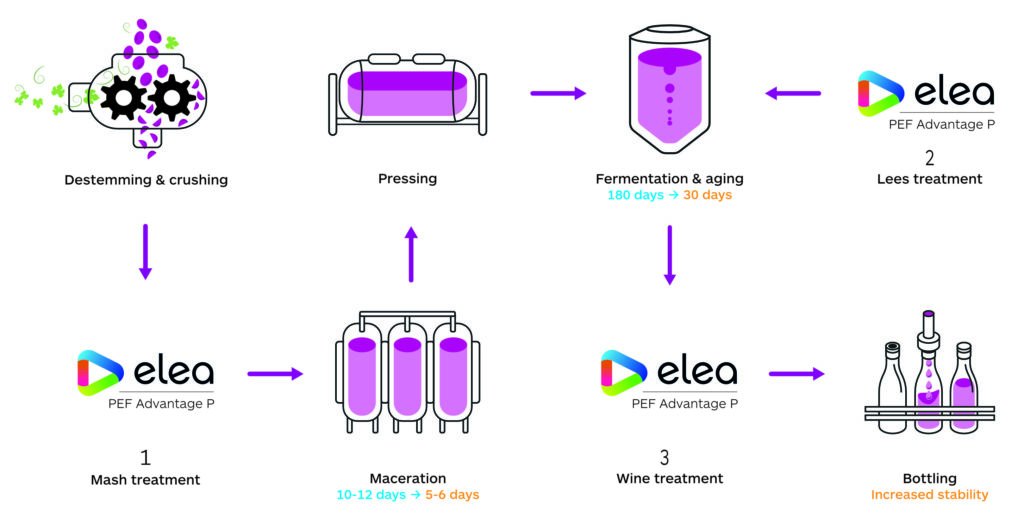

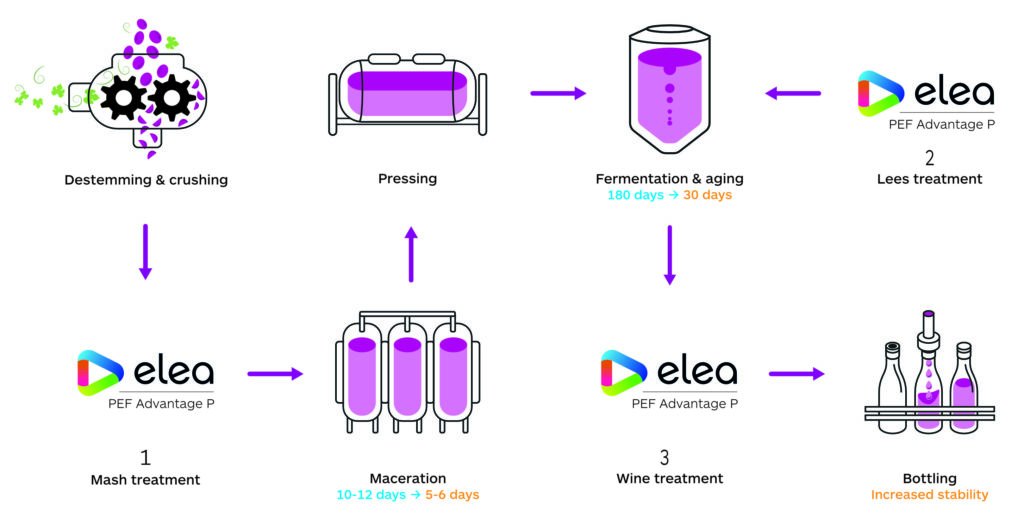

Elea PEF can be applied at 3 separate stages during wine production, treatment of the mash and lees and for vinification processes.

The first PEF treatment gently opens the cell membrane of the freshly mashed grapes. This enhances the extraction of valuable compounds such as polyphenols and aromatic precursors. Faster extraction reduces the wine’s maceration time up to 50%. Improved rotation of the fermentation tanks increases production capacities and leads to less energy and water consumption

A second treatment of the lees accelerates autolysis and releases valuable compounds like polysaccharides, amino acids, and mannoproteins from the cell walls at a much faster rate. A faster yeast autolysis reduces the time of ageing on the lees from 180 days to 30 days. Winemakers can produce more complex wines with a better mouthfeel.

A last and higher intensity PEF treatment gently inactivates spoilage microorganisms and reduces the need for sulphites, without losing taste. Also, it accelerates the release of mannoproteins and aroma-precursors from yeast cells for more intensity and higher quality. Storage time will be shortened, and the wine is more complex and stable for ageing.

Find the right Elea PEF Advantage system for your olive oil and wine production

Elea offers a range of different-sized Elea PEF Advantage Pipe systems suitable for processing olive and grape mash, lees and wine with varying line capacities. Elea systems put control in the hands of the operator and offer customisation of the process parameters. A compact design and small footprint enable easy integration into your production line.

The most suitable PEF solution for olive or wine processing is the Elea PEF Advantage P 1e system. With its all-in-one, compact design and ability to process up to 11 t/h of pumpable products, it fits perfectly in most olive oil and wine production lines.

Reach out to us and book a free 30-minute PEF talk with us. Our PEF experts are keen to answer any open questions and discuss Pulsed Electric Fields’ benefits for wine and olive oil winning. Buy or rent your system for the next harvest season.