Pulsed Electric Field (PEF) opens the cell membrane (electroporation) of fresh produce resulting in significant increases in yield, freshness, flavour and nutritional preservation.

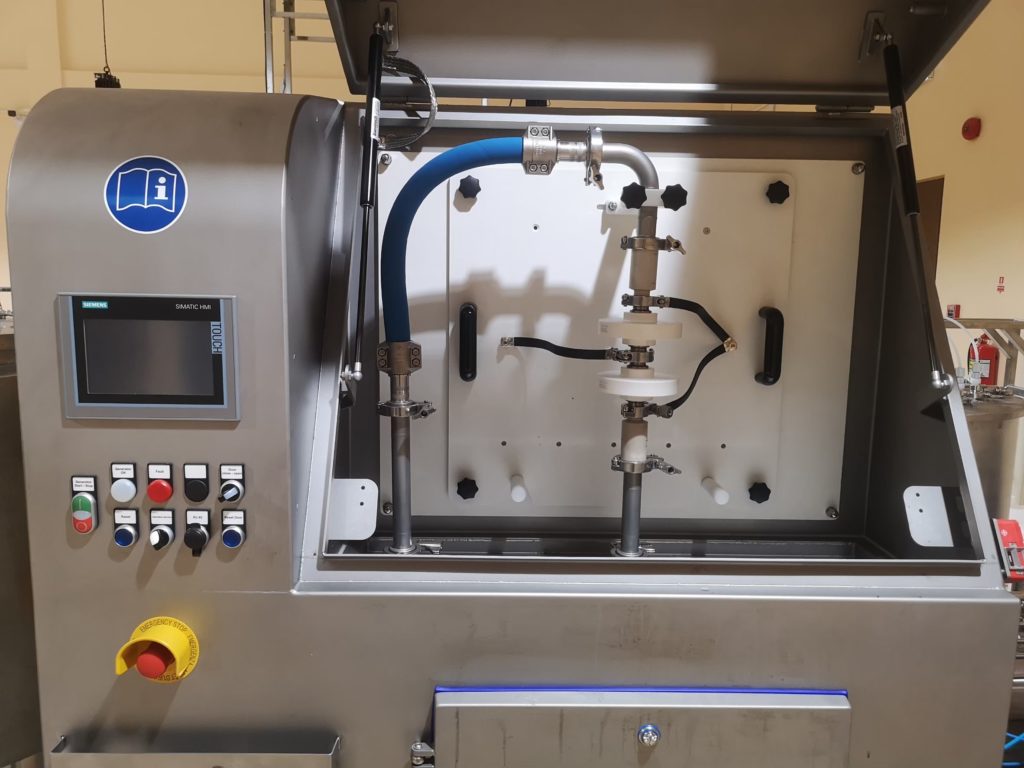

Our Elea PEF Advantage Belt systems improve product quality and yield whilst reducing processing costs. Raw materials treated with Pulsed Electric Field (PEF) are easier to cut or slice and show less breakage. PEF application allows to shorten frying time and temperature and reduces undesired quality changes.

In our online PEFinar, we guide you through the production process of chips and French fries with a focus on the resulting PEF benefits in each step. Our Managing Director Stefan Töpfl and our Scientific Engineer Kevin Hill discuss process benefits first-hand and point out calculations for return of investments and savings in frying oil, energy and water costs.