Water savings

Water savings

Energy savings

Longer knife durability

Smoother surface

Brighter colour

Improved cutting

Higher capacity

New cuts and shapes

New raw material

Faster frying time

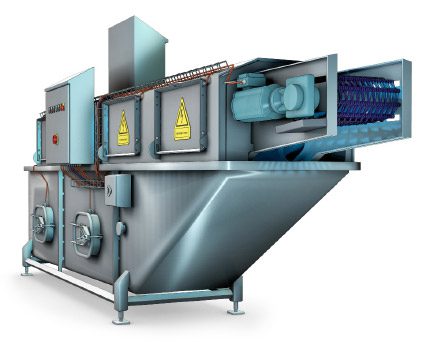

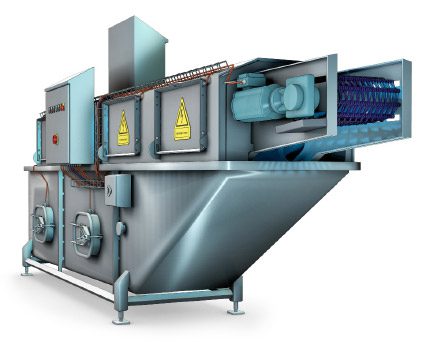

The Elea Pulsed Electric Field belt systems are the optimal solution for the treatment of potatoes for potato chips production.

The SmoothCut system is available in a range of four models: PEF Advantage™ Belt One, 10, 100 & 1000 able to process capacities from 1 t/h up to 60 t/h.

All of them have a quick start-up, small footprint and can be easily implemented into your potato chips line.

Elea PEF systems bring large energy and water savings as well as many process and product benefits.

Low energy use

Less Oil uptake

Brighter colour

Improved texture and crispiness

Enhanced process optimisation

Reduced blade wear

Reduced water consumption

Less heat

Higher capacity

Faster frying time

Faster process times

New cuts and shapes

The Elea PEF Advantage™ Belt Pulsed Electric Field treatment gently causes pore formation in the tuber cell (potatoes, taro etc).

This results in a softer raw material that’s much easier to process and brings added benefit to the production of potato chips. Improved cutting behaviour results in less knife wear and in less breakage.

Elea PEF reduces feathering and enables a smoother surface resulting in less fat uptake. The yield is improved by less breakage and less starch in the process water.

The PEF Advantage™ Belt system saves energy and reduces water consumption.

Because the Elea PEF treatment is a cold process, microbial load is reduced and fortnightly operation intervals become feasible.

The frying time of the potato chips process is reduced which produces a brighter colour in the chips and improves fryer capacity.

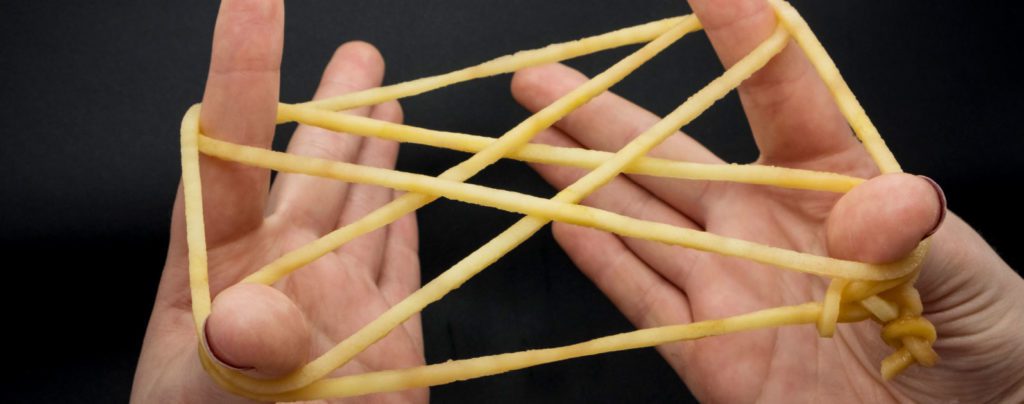

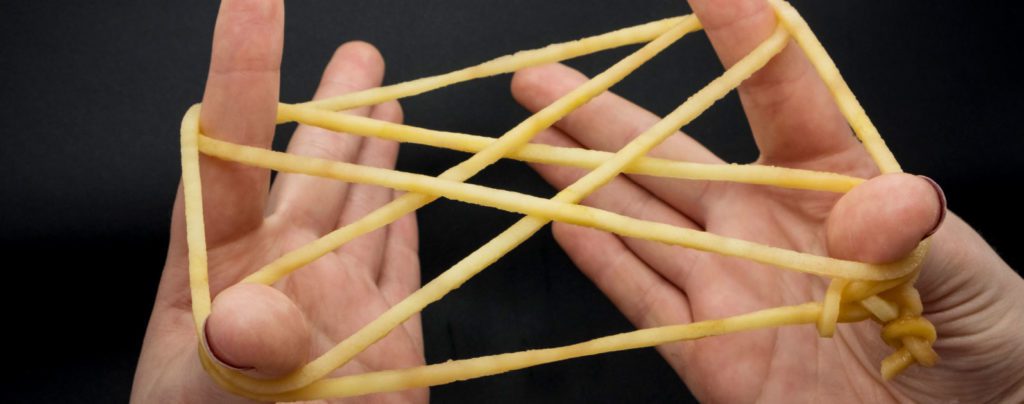

New shapes, new products, greater savings and new opportunities

PEF brings positive and dramatic changes to the potato chip manufacturing process

Elea PEF Advantage™ Belt: saving energy and lowering water usage, increasing yield and improving colour and quality.

PEF brings positive and dramatic changes to the manufacturing process as well as to the actual raw materials themselves.

Through Pulsed Electric Fields, we can create radical new opportunities for food. Elea PEF alters the cell structure and raw materials have their full potential released. For example, here we can see a string made from single potato that has had its

structure altered using PEF. The potato now has the strength and flexibility to maintain its structural integrity and provide new opportunity for product development.

The PEF Advantage™ Belt One. The latest system designed by Elea is a compact industrial scale system for production of potato chips.