Faster extraction, enhanced quality, increased yield, reduced costs, controlled fermentation and spoilage.

Elea Pulsed Electric Field food processing enhances your production line, improves the quality of your product and provides savings in time and energy. PEF opens the cells of fresh produce (electroporation) resulting in significant increases in yield, freshness, flavour and nutritional preservation.

PEF for solid food

New product opportunities

PEF for liquid food

Reduce cost

PEF R&D

Pilot scale

What can Elea Pulsed Electric Field food processing systems do for your product?

Elea Pulsed Electric Field systems use precise and targeted electrical pulses to open the cell membrane (electroporation) of raw products. It’s a clean, gentle and targeted process that can be used to benefit a broad range of products.

PEF for vegetables

Improve vegetable processing with PEF. Up to 50% faster blanching, better cutting and improved flexibility.

PEF for French fries

Improve French fries with PEF. Improve cutting, less fracture, better colour, less oil uptake, reduced blade wear, faster frying time and more.

PEF for veggie chips

Improve veggie chips with PEF. Increase yield, develop new product opportunities, control colour, improve quality and reduce costs.

PEF for drying

Improve drying with PEF. Accelerate drying, improve quality, faster process times and energy savings

PEF for olive oil

Improve olive oil processing at lower temperatures, increase yield and gain more EVOO.

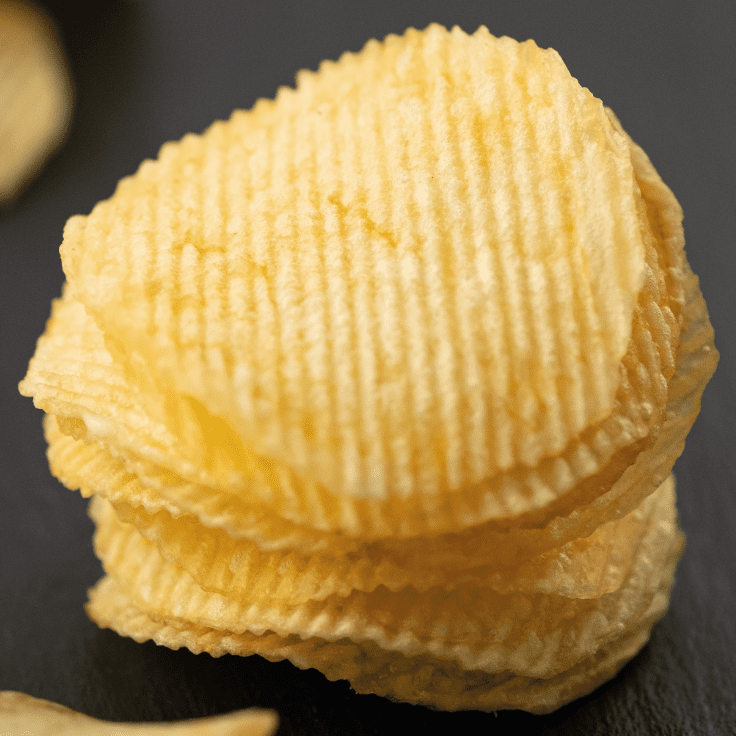

PEF for potato chips

Improve potato chips with PEF. Increase value, enhance production, improve frying control, expand capacity, develop new product opportunities control colour & more.

Find the right Elea PEF Advantage system for your product

We have installed more than 250 Elea PEF systems globally, working for some of the world’s leading food producers. Every Elea PEF Advantage system shares the same 24/7 production capability and is built to operate under extreme conditions.

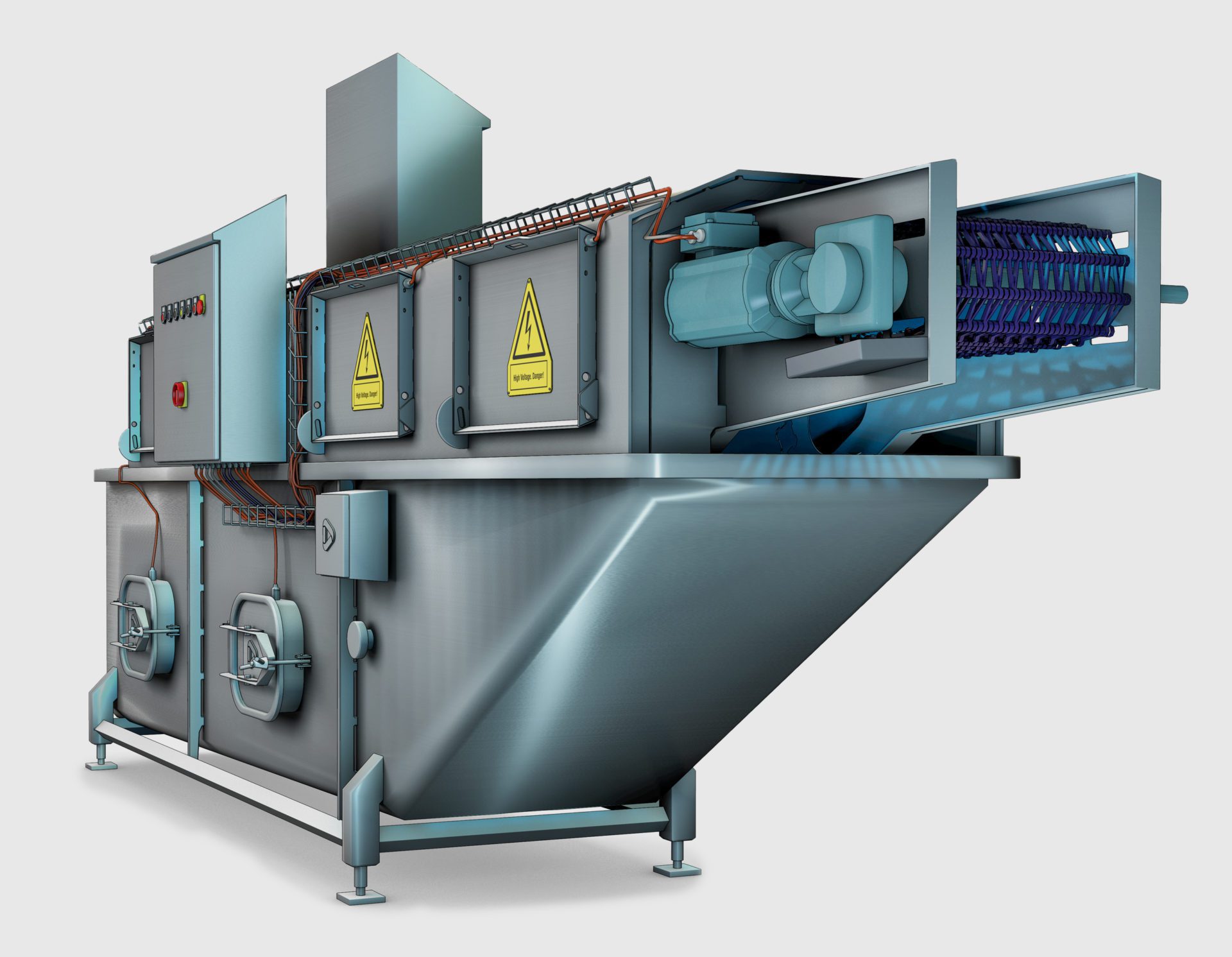

Elea PEF Advantage B 10-535 and B 100-535

Part of our range of all new belt systems for the large-scale treatment of roots, tubers and fruits, the new PEF Advantage B 100-535 (up to 32 t/h) and B 10-535 (up to 20 t/h) are the mid-capacity versions of the B 1000-850.

Fenceless, compact & easy to install.

Improved process monitoring.

Easier integration with extended cable length.

Powered by a single generator.

Greater energy efficiency.

Both models feature the same new features, innovations and high build quality as the B 1000-850.

Elea PEF Advantage B 1000-850

The PEF Advantage B 1000-850 is our highest capacity belt system capable of processing up to 100 t/h of roots, tubers and fruits.

The feature-packed new design improves capacity, flexibility, safety, process monitoring and optimisation, energy saving, installation, upgradeability

and more.

Fenceless, compact & easy to install.

Improved process monitoring.

Easier integration with extended cable length.

Powered by a single generator.

Greater energy efficiency.

The Elea PEF Advantage B 1000-850 is our most capable and advanced large belt system yet.

The Elea PEF Advantage P 1 e

Designed for PEF extraction, the Elea PEF advantage P 1e is an all-in-one, compact system able to process up to 11 t/h of pumpable products.

Hygienic integrated design CIP, SIP ready.

Complete control of process parameters and online monitoring dose to comply with all HACCP requirements. Its modular design is easy to install, configure and maintain.

The Elea PEF Advantage P 1 i

With its all-in-one, compact design, the Elea PEF Advantage P 1 i is able to inactivate up to 500 l/h per hour of pumpable product. Hygienic integrated design CIP, SIP ready.

Complete control of process parameters and online monitoring dose to comply with all HACCP requirements. Its modular design is easy to install, configure and maintain.

PEF Advantage B 1 & B 1 mini

The compact industrial-scale systems for the treatment of vegetables, tubers and fruits. The PEF Advantage B 1 & B 1 mini-systems are built as a single unit including a pulse generator, treatment belt and vessel. The B 1 is designed for treatment capacities up to 7.5 t/h.

The B 1 mini is specially engineered for smaller lines with treatment capacities of up to 3 t/h, with an option to upgrade to B 1 capacity if required.

The Elea PEF Advantage P 10-100

Up to 20 t/h for extraction and 2.500 liter/h for shelf life extension of liquids, subject to process requirements. Hygienic integrated design CIP, SIP ready.

Complete control of process parameters and online monitoring dose to comply with all HACCP requirements. Its modular design is easy to install, configure and maintain.

PEF Advantage B 10, 100, 1000

The industrial scale solution for the treatment of tubers, roots, vegetables and fruits. Our PEF Advantage Belt system are available in a range of four models: the PEF Advantage B 1, B 1 mini, 10, 100 & 1000. Each option is fully customisable to your requirements.

Up to 70 t/h processing capacity, quick start-up, low energy & water consumption.

The Elea PEF Advantage P 1000

Elea PEF Advantage P 1000 up to 30 t/h of pumpable products, subject to process requirements. Hygienic integrated design CIP, SIP ready.

Complete control of process parameters and online monitoring dose to comply with all HACCP requirements. Its modular design is easy to install, configure and maintain.

We have the expertise, the facilities and the experience to help you get the most from Pulsed Electric Field

We take your product concept and apply our industry-leading knowledge and experience to design a system that will deliver you the greatest value. Our scientists and engineers are with you every step of the way, offering expert guidance and professional advice from concept to delivery.

PEF solutions

With more than 250 systems installed globally, we are the world’s most popular PEF solutions provider to the food and beverage industries. Elea PEF Advantage systems are designed and manufactured at our facility in Germany to the highest standards, with each system customizable to your specific requirements.

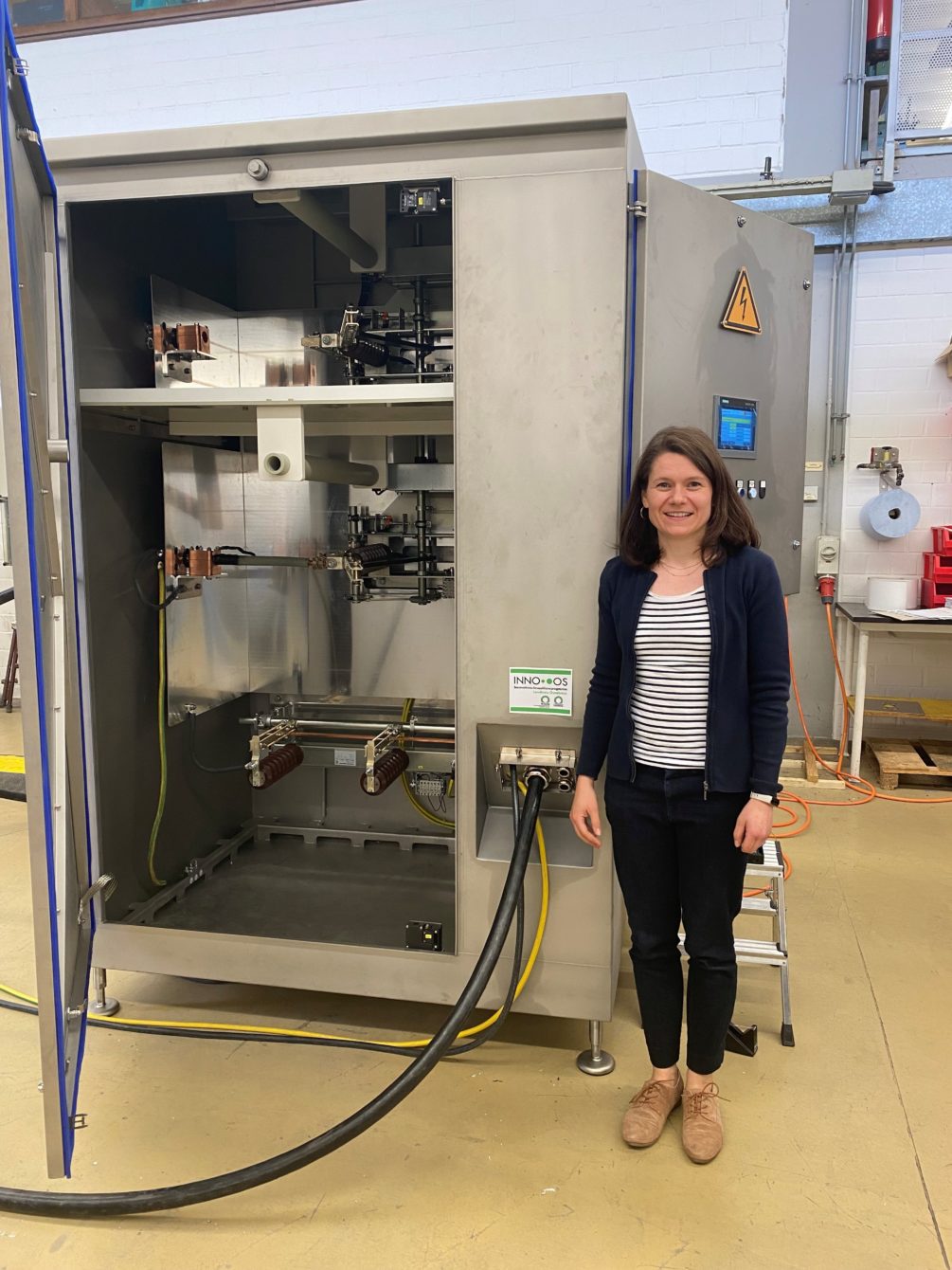

Application support

At Elea, our experts can manage your PEF project from blueprint to production line, on-time and on-budget. Every PEF system we design is tailor-made to your specific needs. We test the efficacy of our PEF system in our custom-built pilot hall here in Quakenbrück, fully equipped with state-of-the-art facilities to emulate your production process.

Technical care & support

With our team of support engineers, options for remote maintenance and on-site spare parts, Elea keep you up, running and efficient.

We offer a full 24-hour support service around the world. Our specialist installation teams work closely with our customers to ensure smooth, swift and successful commissioning of our systems.

Learn more about Elea Pulsed Electric Field Advantage systems and how they can transform your product and enhance your production line

CHIPS & FRIES WITH PEF ADVANTAGE BELT

DRYING WITH PEF ADVANTAGE B 1

JUICE & SMOOTHIES WITH PEF ADVANTAGE PIPE

Working in partnership with our clients to get the best from Pulsed Electric Field

Mr Frank Bianchi, plant manager for Amica chips, talks about Amica’s experience working with Elea, their PEF Advantage systems and the benefits Pulsed Electric Field treatment has brought to the Amica production line.

How Pulsed Electric Field works

How PEF effects solid food

Pulsed Electric Field causes pore formation in the cell membrane of plant and animal products, scientifically known as electroporation. Increased porosity greatly enhances mass transport in the product which provides a wide range of advantages to both products and processes.

PEF’s treatment positively affects nearly all plant and animal cells including, tubers, roots, and fruits.

Elea PEF Advantage B systems enhance cutting ability, produce a less feathered, smoother surface, improve texture and crispiness, increase quality, improve frying, reduce oil uptake, save energy and enable the development of novel product shapes – and much more.

How PEF effects liquid food

PEF inactivates the bacteria in liquid foods at low temperatures providing the perfect alternative to other processing solutions such as pasteurisation or HPP. Pore formation is induced in the bacteria when the PEF field strength exceeds the transmembrane potential, forcing the cell membrane to open, killing the bacteria and extending shelf life.

PEF is a low-temperature process that helps to preserve valuable compounds whilst having a positive effect on the overall quality

of the raw liquid product, retaining more natural nutritional value, including vitamins, antioxidants and pigments, to produce a healthier, fresher and more appetising final product.

The more open pore structure in the plant cell increases extraction potential, and more valuable compounds can be extracted without additional enzymes.

Elea PEF Advantage Pipe systems are low temperature, low maintenance and are designed and engineered for 24-hour continuous operation,

making them the best value juice processing solution.

Elea Pulsed Electric Field Advantage systems, reduce waste, save energy and conserve water

In 2020-21 Elea Pulsed Electric Field systems help to save

tonnes of C02

GJ of energy

m3 of water

Get more for less, greater savings and sustainability with PEF

Elea PEF Advantage systems transform food manufacturing processes – improving output. They can reduce labour water & energy costs, help streamline supply chain logistics and help to minimise retail waste.

Elea Pulsed Electric Field research and development, collaborating with DIL and our industry partners, are driving new opportunities for food processing

PEF SWITCH

Development of a PEF Switch for alternating PEF utilization at multiple food production lines.

Pioneering new PEF applications through partnerships

New Pulsed Electric Field food processing opportunities and innovations are often driven by our collaborative R&D projects. The knowledge gained from this research is directly funnelled into new PEF solutions and applications via the Elea PEF Advantage Belt and PEF Advantage Pipe systems.

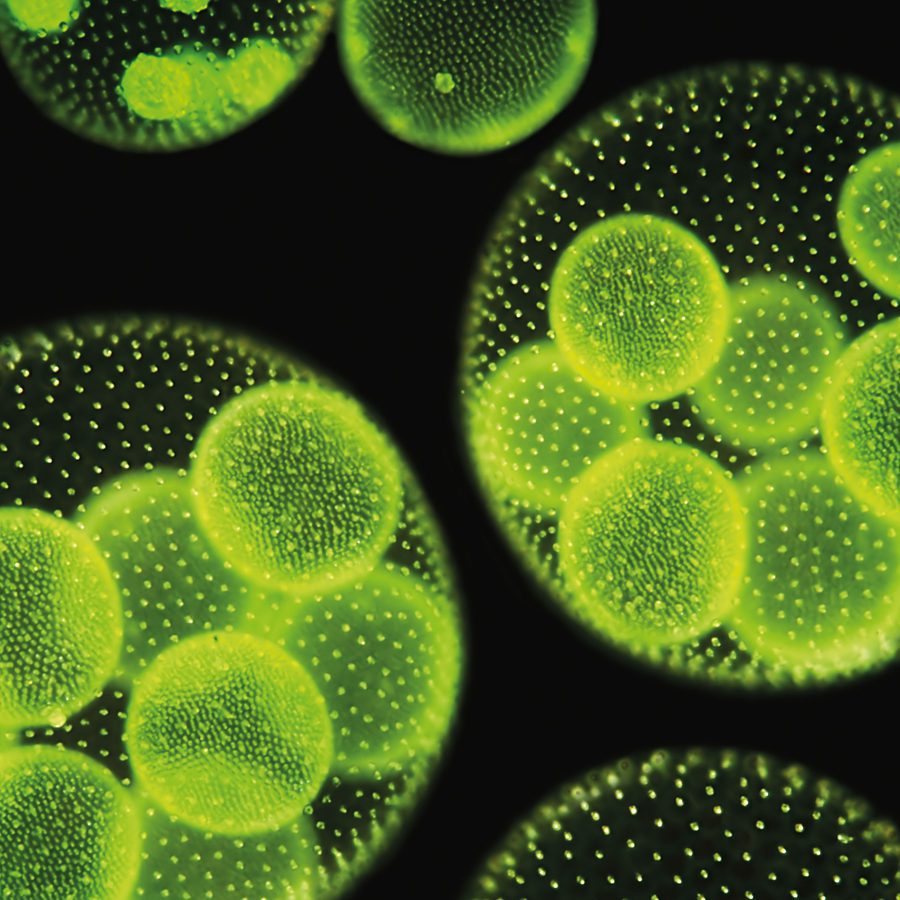

Elea is currently involved in a wide range of PEF collaborative research projects including stimulation of algae for improved growth and extraction, PEF drying optimization for improved quality and form stability and new improvements for meat processing.

Elea has built a valuable network of research partners from both academic and industry backgrounds from all over the globe.

These include research institutes such as the German Institute of Food Technologies (DIL e.V.) and FEI, and universities such as the University of Applied Science of Osnabrück, University Vienna BOKU, CPUT in South Africa and the Warsaw University Of Life Sciences in Poland.