Brighter colour, better taste and longer shelf-life provided by PEF Advantage Pipe

When it comes to processing juices and smoothies, greater yields, improved taste and flavour and minimal loss of nutrients are just some of the benefits of using an Elea PEF Advantage Pipe system.

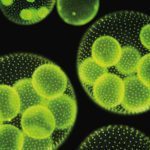

Elea PEF Advantage Pipe systems extend the shelf life of juice, smoothies, milk, wine and other liquid consumables with Pulsed Electric Field and at a much lower temperature than traditional thermal pasteurisation. This means your customers can enjoy higher quality, fresh and colourful juice that hasn’t compromised on essential nutrients or flavour.

Extraction with PEF Advantage Pipe is enhanced with valuable vitamins, colour and antioxidants from fruit processing which ultimately results in higher yields.

Our PEF Advantage Pipe systems create plenty of positive changes to the manufacturing process including less machine down-time. Also, as juices and smoothies have a longer shelf life, it means

that there’s potential for greater market reach and better distribution of your product.

The PEF Advantage Pipe range of systems have processing capacities from 50L to 10,000L per hour and each individual system has a hygienic integrated design that is both CIP and SIP ready.

Our Pulsed Electric Field systems put control in the hands of the operator and mean that our clients have full customisation of the process parameters. The modular design of the PEF Advantage Pipe system is simple to configure and easy to maintain and what’s more, close monitoring ensures compliance with all HACCP requirements.

Elea PEF Advantage P 1, 10, 100, 1000

PULSE GENERATOR

Touch screen, measurement of peak voltage and current, connectors for oscilloscope, safety interlock, emergency.

Air and water cooled depending on system.

Dependent on system, stainless steel cabinet.

Continuous Treatment Chamber

Up to 10 000 l/h of pumpable products, subject to load ratio and process requirements.

SERVICES REQUIRED

400/415 V, 50 Hz, (3Phase/Ground). Other options available.

CAREFULLY CONSIDERED MANUFACTURING

Each Elea PEF Advantage Pipe system is expertly designed before being manufactured in our innovative facility in Quakenbrück, Germany.

CONSTANT OPERATION

Our PEF engineers manufacture our PEF Advantage Pipe systems to the highest quality. Optimum performance is an absolute must, so we design them to operate under extreme conditions with minimal downtime.

Even with constant operation, our PEF Advantage Pipe systems have proved their durability time and time again and only require minimal maintenance.

We have a range of service support contracts including 24/7/365 emergency care, remote monitoring and performance care upgrade programmes, which are all undertaken by our expert technical team.

TAILORED TO YOU

From the initial design process, right through to manufacturing and software programming, our team of experts can create innovative solutions to enhance your PEF Advantage Pipe system.

Working in partnership with our customers, we listen, develop and implement bespoke solutions that will help to release the potential of their products and customise the treatment of the cells.

A great working relationship with the manufacturing team means that we can create PEF Advantage Pipe systems that fulfil their purpose and create fantastically fresh and flavourful juices.

CONTROLLED OUTPUT

Our PEF Advantage Pipe systems are simple to operate and can be fully controlled by our customers’ in-house teams, even down to customising the process for each liquid consumable type.

At Elea, we design our PEF Advantage Pipe machines to fit seamlessly into existing production lines and include fully controllable, certified and accredited systems that can be installed anywhere across the globe.

We closely monitor each of our PEF Advantage Pipe systems to ensure that food safety risks are reduced and our clients can meet compliance HACCP requirements.

Does the PEF Advantage Pipe system require a full-time operator?

Our PEF Advantage Pipe have no need for a full-time operator.

How frequent is maintenance required on the PEF Advantage Pipe system?

To ensure a correct system calibration, correct PEF Advantage Pipe system function and mechanical health, we recommend that your system receives a monthly PPM that takes only an hour. In addition, we like to provide an annual inspection from our Elea service team. Our CoolJuice™ machines have almost no wear parts, and this is something that we are constantly trying to innovate in order to further reduce maintenance needed.

How have you considered the parts that come into contact with the product?

We’ve ensured that all parts of the PEF Advantage Pipe system that come into contact with the product are food grade. Made with either stainless steel or CE and FDA listed plastics, we include certification with each system’s documentation.

How have you treated the metal parts of the PEF Advantage Pipe system?

As well as being grit polished during the production process and after welding, all metal parts of the PEF Advantage Pipe system are made using stainless steel 1.4301 or higher.

Is the PEF Advantage Pipe able to be remotely controlled?

We can log in from our office to help with any problems, and have also made it possible to download data, link to any factory Scada system and gain remote control of the PLC as if you were in the same room.

How easy is it to replace PEF Advantage Pipe system parts?

It’s very easy. To make things easy, not only do our electronic parts require no more set up than simply plugging in, but we have

designed our PEF Advantage Pipe machines in a way that makes part replacement simple and quick.

Is there a specific cleaning solution needed to clean the PEF Advantage Pipe system?

Not at all. Simply use the food industry-friendly cleaning solutions that you favour when it comes to the upkeep of our easy-to-access PEF Advantage Pipe system.

Which utilities does the PEF Advantage Pipe require?

As well as water and electric, the PEF Advantage Pipe system also needs compressed air and separate water to cool the generator.

What training is available for our PEF Advantage Pipe systems?

Not only do we offer training for operators, but we’ve also developed a programme for maintenance personnel too. During the installation, you’ll be provided with training material that’s relevant to your specific bespoke PEF Advantage™ Pipe system. If you feel that you require further training, we welcome a visit from your team to our facility in Quakenbrück, Germany.

Are the PEF Advantage Pipe electric cabinets safe in the wet?

Yes. We’ve made sure that our electric cabinets are designed to be suitable for wet areas.

Can the PEF Advantage Pipe generators be cooled with a closed loop water chiller?

Whether you prefer to use glycol or water (typically at a minimum temperature of 15°C) in your PEF Advantage Pipe, you are more than welcome to specify a closed loop circuit for cooling.

Does PEF evenly treat the whole product?

Not only does the PEF Advantage Pipe treat the whole raw product, but it does so evenly and uniformly.

PEF ADVANTAGE PIPE SYSTEM INSTALLATION & AFTERCARE

Not only do we offer full training during the installation of your PEF Advantage Pipe, but we offer comprehensive aftercare too.

TRAINING

The training for maintenance personnel and operators of your PEF Advantage Pipe system is tailored to the exact customisation of your machine. To ensure your staff are highly-skilled and will get the most out of your PEF Advantage Pipe system, our experienced technical team are there to help.

Our PEF Advantage Pipe training thoroughly covers best possible yield, up-time, settings and safety, and can be carried out either at your offices, or ours if you wish.

SUPPORT SERVICES

No matter where in the world our PEF Advantage Pipe systems are installed, we provide comprehensive support. Our highly-trained technical team travel the globe to support our clients from installation right through to the ongoing maintenance programme.

If you need our help quickly, we can also remotely monitor your PEF Advantage Pipe system at any time of day and run diagnostics if needed. Our knowledgeable Customer Service department is here to help should you need them.

MAINTENANCE

To ensure that you’re getting the most out of the running of your PEF Advantage Pipe system, it’s essential that the machine has a proper maintenance schedule, and should a part need to be repaired or replaced, it’s done quickly and efficiently.

Our preventative service inspections, training and maintenance programme are provided to give our clients peace of mind, but should anything happen, we’ll make sure any down-time or impact to your business is minimised.