Faster extraction, enhanced quality, increased yield, reduced costs, controlled fermentation and spoilage.

PEF for vegetables

Improve vegetable processing with PEF. Up to 50% faster blanching, better cutting and improved flexibility.

PEF for French fries

Improve French fries with PEF. Improve cutting, less fracture, better colour, less oil uptake, reduced blade wear, faster frying time and more.

PEF for veggie chips

Improve veggie chips with PEF. Increase yield, develop new product opportunities, control colour, improve quality and reduce costs.

PEF for drying

Improve drying with PEF. Accelerate drying, improve quality, faster process times and energy savings

PEF for olive oil

Improve olive oil processing at lower temperatures, increase yield and gain more EVOO.

PEF for potato chips

Improve potato chips with PEF. Increase value, enhance production, improve frying control, expand capacity, develop new product opportunities control colour & more.

Elea PEF Advantage systems transform manufacturing – improving output, reducing labour costs, streamlining supply chain logistics and helping minimise retail waste.

We are the world’s leading supplier of Pulsed Electric Field solutions; we offer:

PEF Advantage systems

The world’s most popular, tried and tested PEF systems. Designed and manufactured by Elea in Germany to the highest standard. Tati ra nullaolupta simil ium rehende dolor remque veliquam fugitis.

Application support

At Elea our experts can manage your PEF project from blueprint to production line, on-time and on-budget. Every PEF system we design is tailor-made to your specific needs.ati ra nullaolupta simil ium

Techinical care & support

We cover a full 24 hour support service around the world. Our specialist installation teams work closely with our customers to ensure a smooth, swift and successful commissioning of our systems…

Learn how Elea Pulsed Electric Field Advantage systems can transform your product and enhance your production line

PEF Juice & Smoothies with PEF Advantage Pipe

PEF Chips & Fries with PEF Advantage Belt

PEF Drying with PEF Advantage B 1

Elea PEF systems are transforming manufacturing processes – improving output, reducing labour costs, streamlining supply chain logistics and helping minimise retail waste.

Find the right Elea PEF Advantage system for your product

We have installed more than 175 Elea PEF systems globally, working for some of the world’s leading food producers. Every Elea PEF Advantage systems share the same 24/7 production capability and are built to operate under extreme conditions.

PEF Advantage B 1 & B 1 mini

The compact industrial-scale systems for the treatment of vegetables, tubers and fruits. The PEF Advantage B 1 & B 1 mini-systems are built as a single unit including a pulse generator, treatment belt and vessel. The B 1 is designed for treatment capacities up to 7.5 t/h.

The B 1 mini is specially engineered for smaller lines with treatment capacities of up to 3 t/h, with an option to upgrade to B 1 capacity if required.

PEF Advantage B 10, 100, 1000

The industrial scale solution for the treatment of tubers, roots, vegetables and fruits. Our PEF Advantage Belt system are available in a range of four models: the PEF Advantage B 1, B 1 mini, 10, 100 & 1000. Each option is fully customisable to your requirements.

Up to 70 t/h processing capacity, quick start-up, low energy & water consumption.

Elea PEF Advantage systems have a fully flexible processing capacity. Able to process a single potato or a full load with no impact on the PEF treatment and putting you fully in control of your production planning. All Elea systems are designed to be easily and fully integrated into your existing production line with minimal disruption.

Application support & pilot hall testing

We have the facilities and the expertise to help you get the most from Pulsed Electric Field.

We take your product concept and apply our industry-leading knowledge and experience to design a system that will deliver you the greatest value. We test the efficacy of our PEF system in our custom-built pilot hall here in Quakenbrück, fully equipped with state-of-the-art facilities to emulate your production process.

Our scientists and engineers are with you every step of the way, offering expert guidance and professional advice from concept to delivery.

In 2020 Elea PEF Advantage systems help to save

tonnes of C02

MWh

Litres of water

Get more for less, greater savings and sustainability with PEF

Elea PEF Advantage systems transform manufacturing processes – improving output. They can reduce labour water & energy costs, help streamline supply chain logistics and help to minimise retail waste.

Meet the Elea Team

Elea is made-up of the best scientific and technical minds in the sector from process engineers, food and bio technologists, mechanical and electrical engineers – all of whom specialise in PEF.

Our Research and Development team in collaboration with DIL and our industry partners are driving new opportunity for PEF

PEF SWITCH

Development of a PEF Switch for alternating PEF utilization at multiple food production lines.

Pioneering new PEF applications through partnerships

New Pulsed Electric Field opportunities and innovations are often driven by our collaborative R&D projects. The knowledge gained from this research is directly funnelled into new PEF solutions and applications via the Elea PEF Advantage™ Belt and PEF Advantage™ Pipe systems.

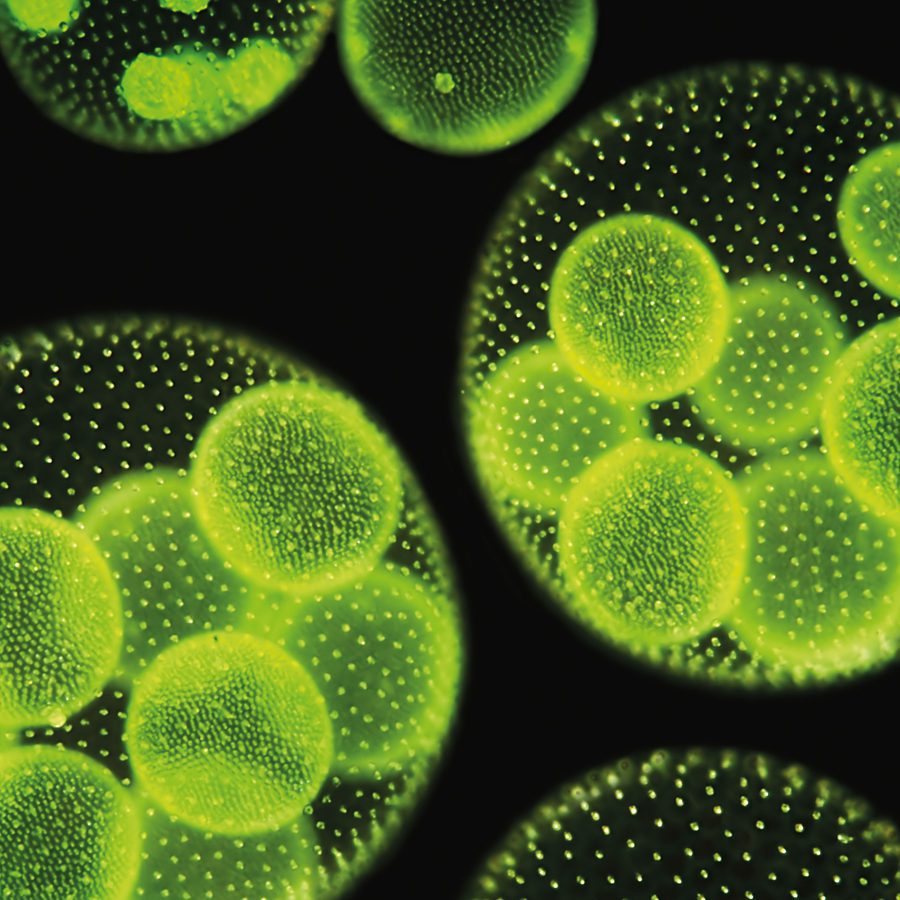

Elea is currently involved in a wide range of PEF collaborative research projects including stimulation of algae for improved growth and extraction, PEF drying optimization for improved quality and form stability and new improvements for meat processing.

Elea has built a valuable network of research partners from both academic and industry backgrounds from all over the globe.

These include research institutes such as DIL and FEI, and universities such as the University of Applied Science of Osnabrück, University Vienna BOKU, CPUT in South Africa and the Warsaw University Of Life Sciences in Poland.