PEF impact in potato and vegetable processing, extraction, yeast management and juice preservation

On November 16 and 17, we have hosted our annual PEF Advantage Day in our PEF facilities in Quakenbrück, Germany. We have welcomed interested visitors and partners from all over the world to demonstrate the technology of Pulsed Electric Fields (PEF) and its benefits and potential for the food and beverage industry.

The first part of our wide-ranging program started with expert presentations on the benefits of PEF in various applications in food and beverage production (Stefan Töpfl, Elea Managing Director), as well as the positive effect of PEF in texture management of vegetables and fruits (Claudia Siemer, Elea R&D Manager).

Two guest contributions discussed application case studies, Marianna Giancaterino, Associate Researcher at the BOKU University of Natural Resources and Life Sciences Vienna talked about the PEF impact on freeze drying and cherry kernel debittering. In her presentation, she explained: “PEF enables gentle processing without loss of quality and with lower water and energy consumption”. Later, Artur Wiktor, Associate Professor at Warsaw University of Life Sciences outlined the PEF influence on product characteristics during drying. “What is particularly advantageous about the PEF process is that the technique can be combined with all conventional drying methods whether air-drying, freeze-drying, microwave or osmotic drying.”

The live demos have focused on the PEF effect on vegetable processing, extraction, yeast management and juice preservation. Our Elea R&D team of food engineers has prepared many product examples so that our guests were able to taste and feel the results of a PEF treatment.

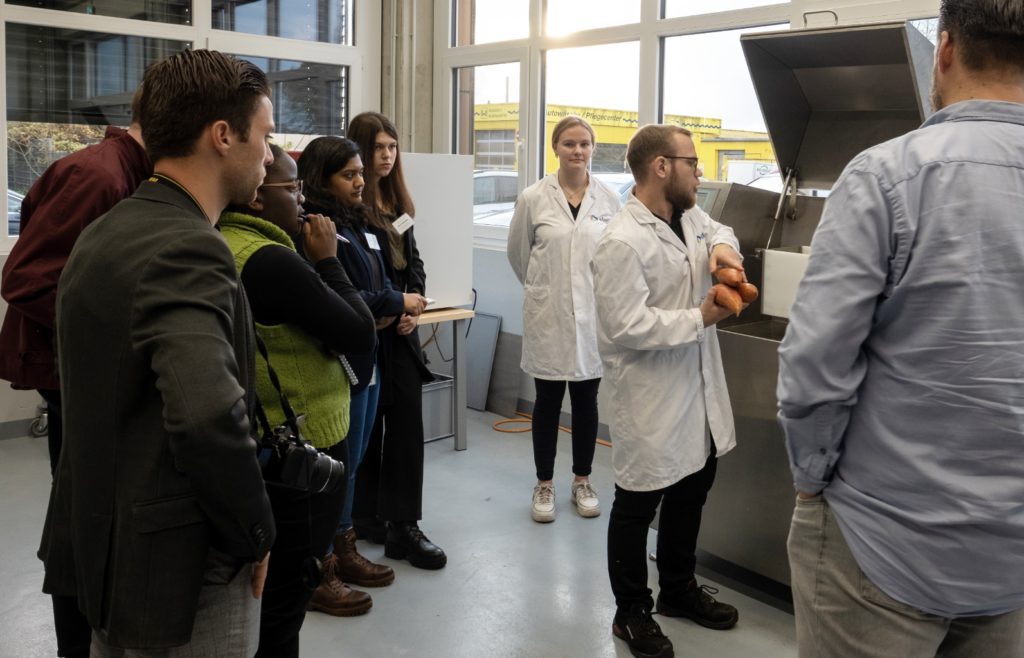

The demonstrations took place in our in-house pilot halls, which are fully equipped with state-of-the-art facilities to emulate production processes. Our snack experts Kevin Hill and Madita Kirchner presented the PEF treatment of vegetables. To show how PEF softens the tissues, our team was treating sweet potato tubers and celery. Raw materials treated with PEF are easier to cut or slice and show less breakage. PEF application allows the reduction or replacement of blanching, shortens frying time and temperature and reduces undesired quality changes. Our guests had the opportunity to try by themselves how easy it is to cut the roots after PEF and could try some freshly fried potato chips.

The impact on drying was demonstrated with samples of strawberries and carrots. It was presented how PEF can shorten freezing and drying times and consequently save energy and increase line capacity. In addition, PEF-treated products retain better colour and shape after drying.

PEF opens pores in the cell membrane, using a precise, targeted and rapid electrical pulse. It enhances the extraction of valuable compounds such as polyphenols and aromatic precursors. This is especially interesting for the production of wine or extra virgin olive oil with a focus on high yield and high quality.

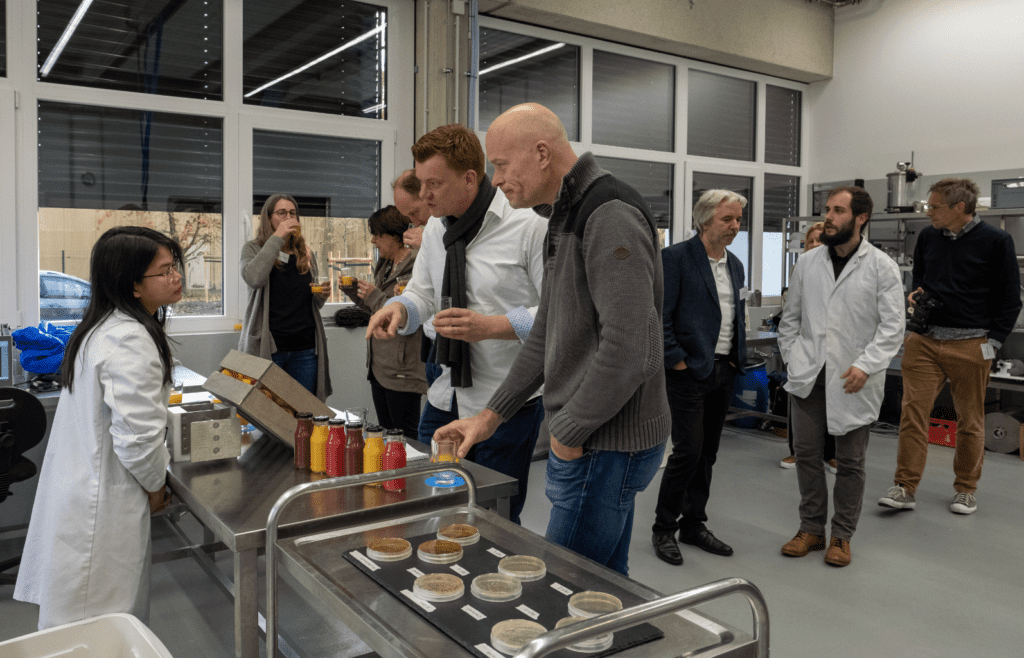

Improved extraction results in faster processing, enhanced quality, increased yield and reduced energy & water savings. The extraction of colour was demonstrated by treating a beetroot and release of water-soluble betalains. After a short time, a difference in extraction was easily visible. Furthermore, our team was manufacturing carrot juice from untreated and PEF-treated carrots. Same as for colour extraction, the demos gave a simple but impressive showcase for PEF-induced yield increase.

In our liquids pilot hall, Marc Schmidt and Nina Siebels treated freshly squeezed orange juice with our new PEF Pilot system. Using plate counting as well as microscopic images, they showed how the number of microorganisms being reduced after PEF treatment, making the juice longer lasting. With juice samples from one of our customers Hoogesteger, the participants had the chance to convince themselves of the consistent quality in colour, freshness and taste.

Corinna Stühmeier-Niehe, together with Arisa Thamsuaidee, then showed the PEF application potential for yeast cells. On the one hand, yeast growth can be stimulated, but there are also considerable advantages for yeast extraction. More yield of valuable compounds (oil, proteins, amino acid, flavour, etc) is a result of applying the gentle and resource-saving technology for cell disruption.

For dinner, we met in a former greenhouse converted into an events location nearby and closed the day with great conversations and drinks. The next morning, we continued with an overview of current research projects in which Elea is involved. Elea is partner or coordinator of regional, national and EU-funded research projects. To us, a strong link to academic society is key for continuous development of new applications and equipment development.

A guided tour through our system showroom by our Elea Engineering manager Jimmy Kinsella gave a great impression of the full range of PEF systems. R&D-oriented systems can treat up to 10 L in batch mode and up to 250 l/h in continuous mode, whereas industrial scale systems reach up to 100 t/h for solid products on processing belts or 5.000 l/h of liquid products in continuous pipe treatment. The tour also included our latest PEF Advantage 1000- 850 belt design.

The tour has been followed by a lunch invitation including Elea PEF treated French fries, as well as a vegan German Currywurst, a new development of the German institute of Food Technologies (DIL e.V.) on basis of pea protein. The afternoon was then spent with one-to-one meetings and demonstrations, in which we could offer our guests Elea PEF solutions tailored to their businesses.

We were extremely pleased to host this great event with lots of interaction between wonderful guests and a strong commitment from our team. We are looking forward to our next in-house event early next year.

In the meanwhile, meet us at Interpom 2022 at our booth No. 224 and find out more about our new system range: elea-technology.com/events/interpom-2022/