Process up to 100 t/h, reduce cost, save energy,

easy installation and increased safety

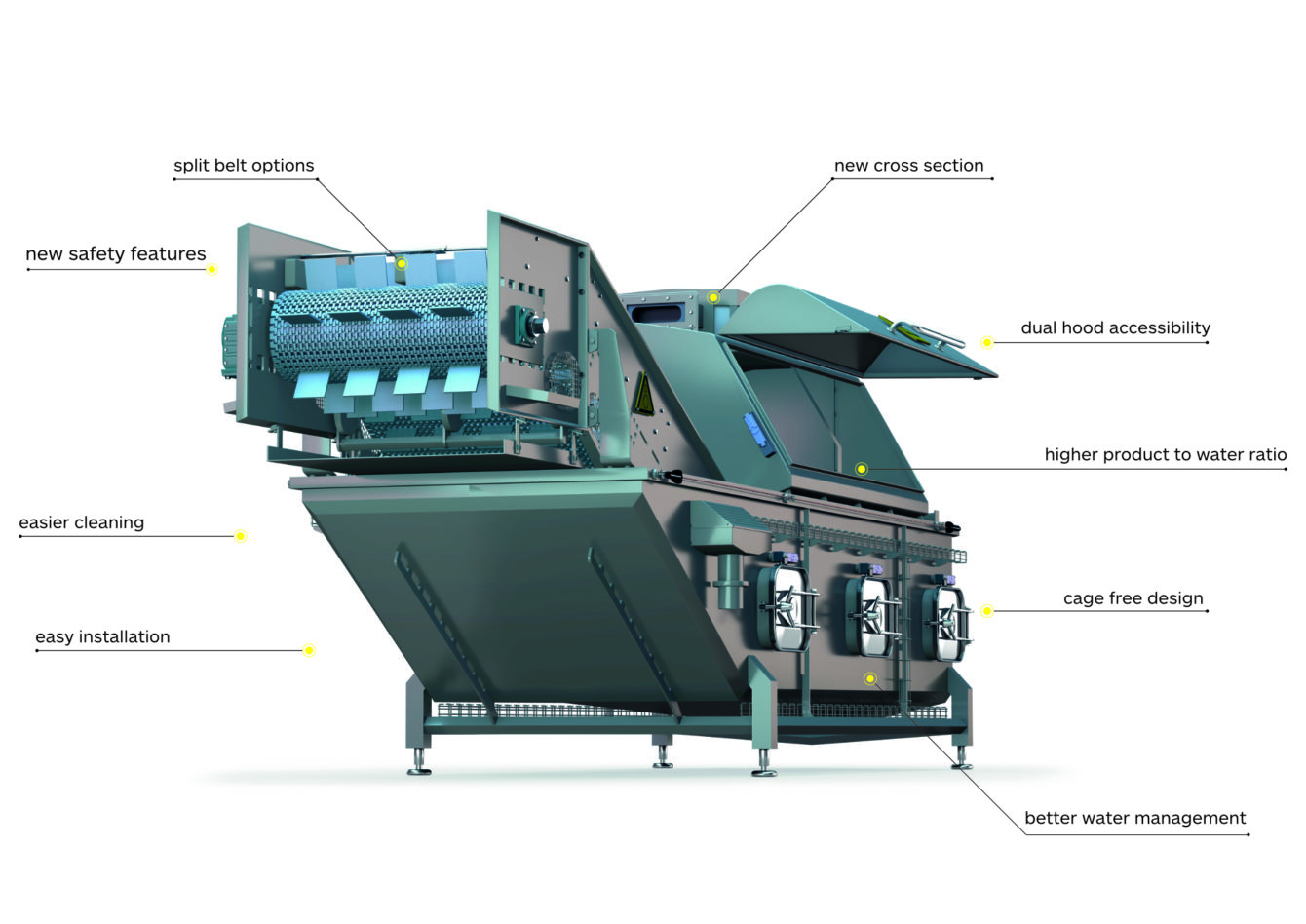

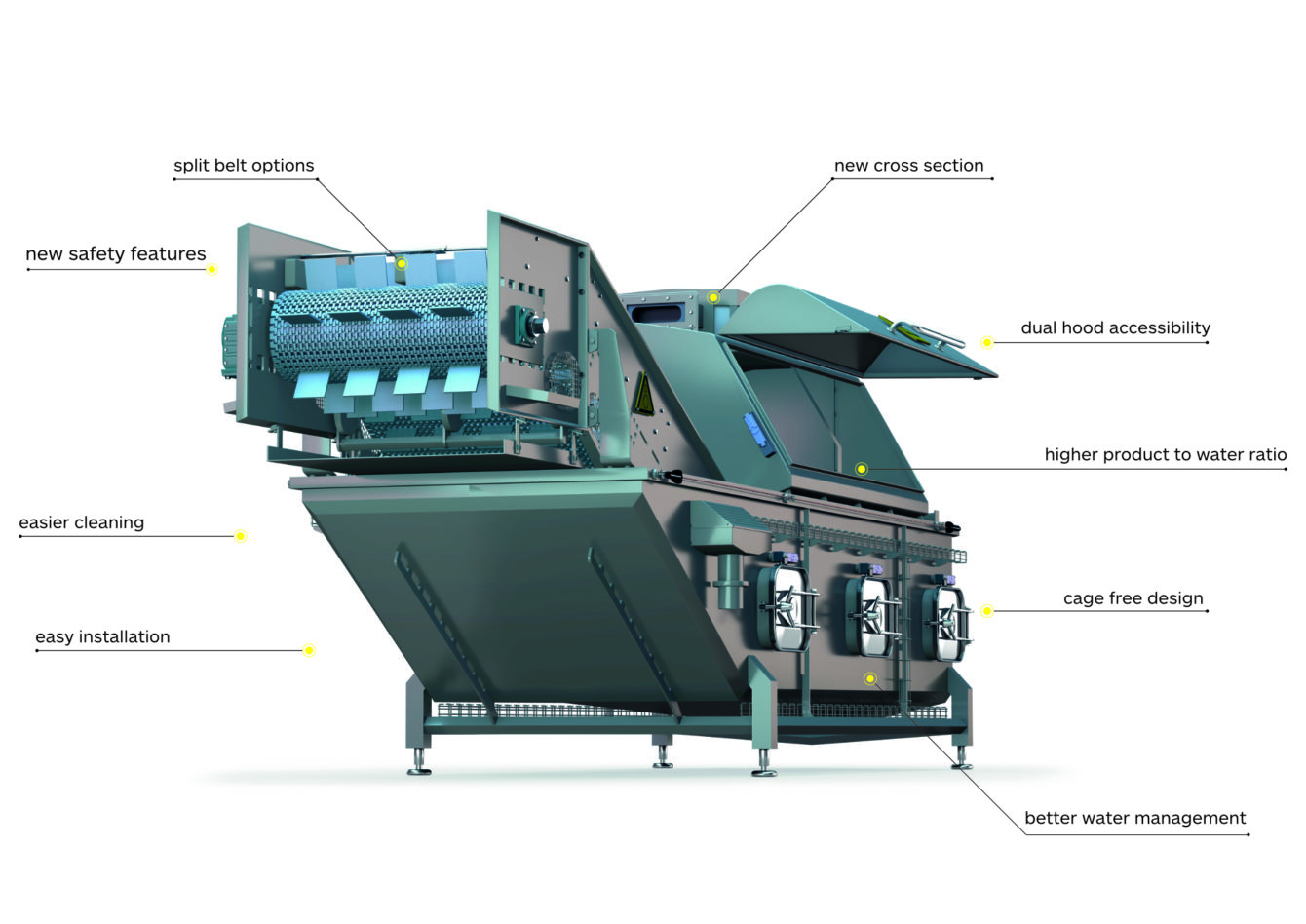

Elea introduces its new B1000-850 system design, the highest capacity belt system to date. With all safety features included in the belt vessel, the design enables processing of up to 100 t/h with a compact, easy-to-install footprint. The largest free cross-section on the market and optimized product in- and outfeed allow a high product-to-water ratio with only generator required.

Other new features include new pulsed power connections with extended cable length, a range of belt types with enhanced belt lifetime, integrated belt motoring, improved water management, and cleaning. The design is fully suitable for sinking and floating products

Available options also include split belt options for multiple products, anti-foam dosing and automated conductivity control.

Stefan Toepfl, Managing Director at Elea: “Our team´s development work has focused on increasing capacity with reduced energy and water requirements. We have distilled ten years of experience, process know how and user feedback into the design, enabling our clients to process more for less.”

In addition to the B1000-850, Elea presents the new B100-535 system design and will promote upgrades on the B1 design, the PEF Pilot range and new process control options.

Watch our video and discover the new features

Meet us at Interpom 2022 at our booth No. 224 and find out more about our new system range: elea-technology.com/events/interpom-2022/